What does a stepper motor do?

-

Automation

-

Health & wellness

-

Life environment

-

Automotive

-

Space

30 Sep. 2025

A stepper motor is a compact motor that rotates its shaft in precise, incremental steps.

If you are designing a product that involves motion such as rotating, moving or positioning components, a stepper motor may be a suitable option. This article explains what stepper motors do, how they work and where they are most effective. You will also learn how they compare to other motor types and what design advantages they offer, even if you are not a motor specialist.

- What does a stepper motor do? What is its role?

- How does a stepper motor work?

- Types of stepper motors

- Why are stepper motors chosen? Key features

- Stepper motor common applications: when should you use one?

- Stepper motor products and application mapping

- Limitations and considerations

- Overcoming your problems with stepper motors

What does a stepper motor do? What is its role?

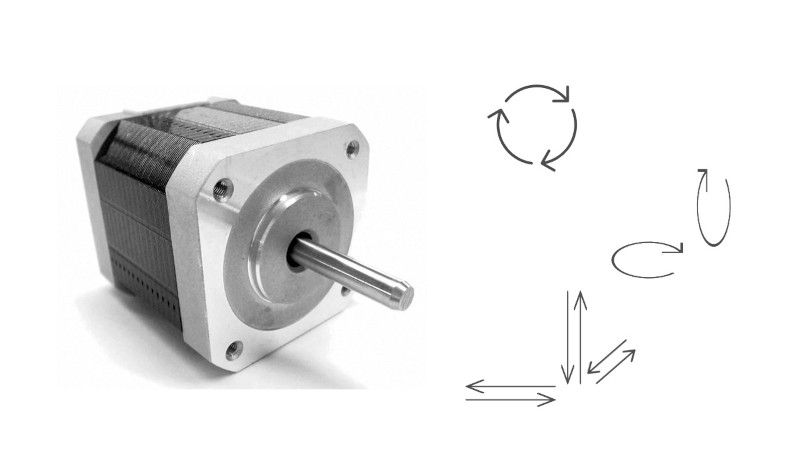

Stepper motors are used to move and stop objects at precise positions and repeat these actions reliably. They are well suited for rotating and moving objects at low speeds, as well as holding objects in place. When combined with mechanisms like lead screws, they can also perform linear and opening/closing motions.

Examples of movements enabled by stepper motors

- Moving and rotating nozzles and ink heads in 3D printers etc.

- Rotating rollers to feed and sort paper or banknotes

- Rotating driving rollers in belt conveyors

- Positioning tools, nozzles, or tables in CNC (Computer Numerical Control) machines

- Panning and tilting lights or projectors in stage/stadium lighting

- Pushing syringes in syringe pumps

- Bending and rotating robotic arms

- Moving blades of louvers in air conditioners etc.

- Deploying and orienting solar panels on space satellites

- Operating valve mechanisms

- Panning and tilting surveillance cameras

- Adjusting directions of auto-tracking apertures (antennas) on space satellites

- Rotating and positioning sample stages in semiconductor manufacturing equipment (SME) or analyzers

While other motor types can perform similar tasks, stepper motors offer the following key advantages that make control systems simpler and more cost-effective:

- Open-loop position control

- Easy implementation of precise positioning

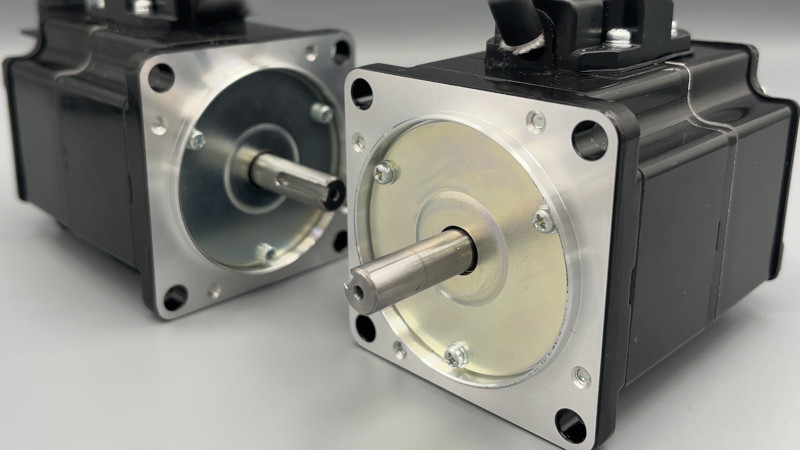

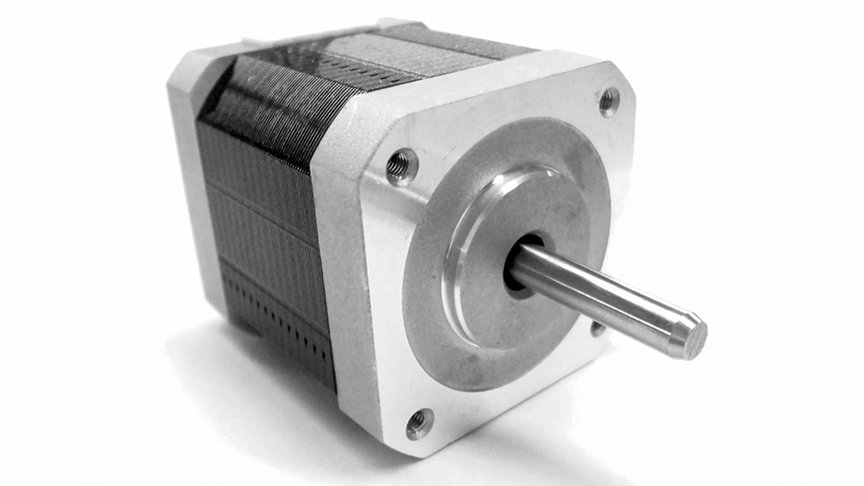

Appearance of a stepper motor

Appearance of a stepper motor

How does a stepper motor work?

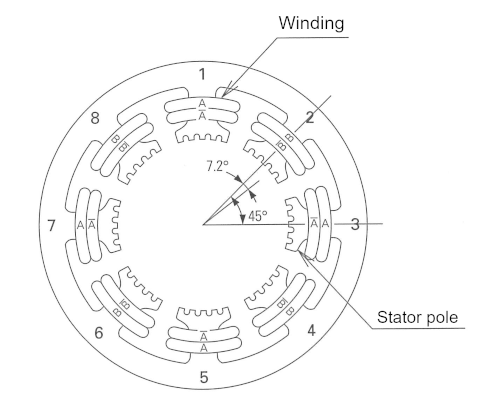

Unlike motors that rotate continuously, stepper motors rotate in small, fixed-angle steps. This is the origin of the name “stepper.” For example, a typical 2-phase hybrid stepper motor rotates in 1.8° increments, and some models can achieve 0.9° steps. With advanced driving methods, even finer steps are possible.

Each pulse signal from the controller causes the stepper motor to rotate by one step. As long as pulses are applied, the motor continues to rotate. When pulses stop, the motor holds its position.

The rotation speed and angle can be easily controlled by adjusting the pulse frequency and count; lower frequency for slower rotation, more pulses for larger rotation angle.

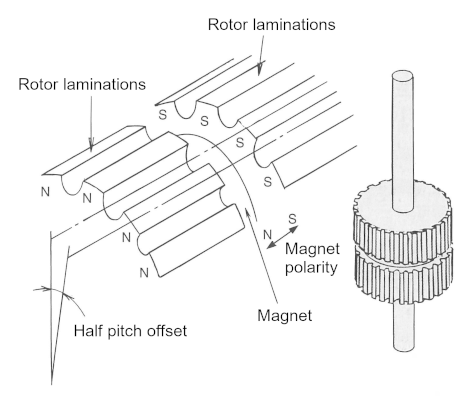

In hybrid stepper motors, the rotor has fine teeth (e.g., 50 or 100), magnetized by permanent magnets. These teeth are attracted to the stator’s magnetic poles, causing rotation. Each pulse changes the magnetic polarity of the stator, causing the rotor to move step by step.

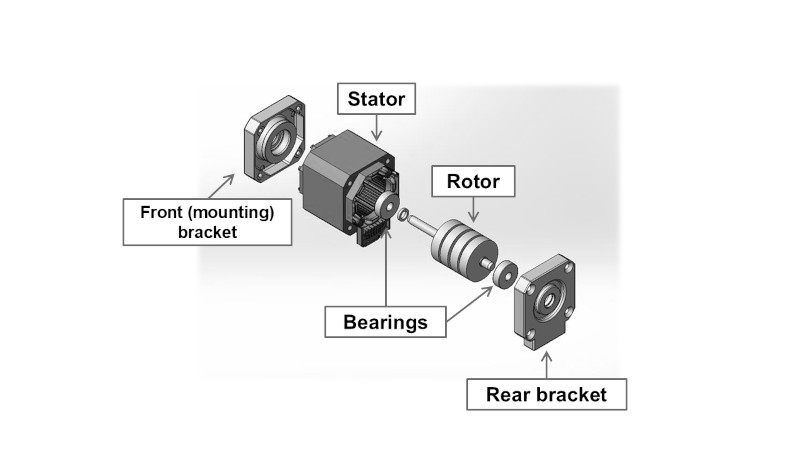

Basic structure of a stepper motor

Basic structure of a stepper motor

Rotor design of a hybrid stepper motor

Rotor design of a hybrid stepper motor

Stator design of a hybrid stepper motor

Stator design of a hybrid stepper motor

Types of stepper motors

Stepper motors can be classified in several ways. In this chapter, we focus on classification by structure and by how current flows through the coils. The optimal type depends on your application’s torque, size and cost requirements.

By structure

- PM type (Permanent Magnet)

- This type uses a magnetized rotor. It offers high torque at low speed, but limited step resolution.

- VR type (Variable Reluctance)

- This type uses a toothed iron rotor. It allows fine step angles (e.g., 1.8°) but has no holding torque when unpowered.

- HB type (Hybrid)

- HB type uses both a permanent magnet and a toothed iron core in the rotor. It combines the advantages of PM and VR types, enabling high-precision positioning along with strong rotational and holding torque. It is widely used in various applications. ASPINA exclusively manufactures hybrid stepper motors.

By coil driving method

- Unipolar

- Current flows in one direction per coil. Simple and low-cost, but lower torque.

- Bipolar

- Current flows in both directions. More complex control, but higher torque.

Why are stepper motors chosen? Key features

Stepper motors are widely used because of the following advantages:

Minimal sliding parts for extended service life

Stepper motors contain fewer components that wear out due to friction, such as gears. As a result, they offer relatively long operational life.

No position feedback required, simple pulse-based control to achieve precise positioning

Unlike other motor types, stepper motors do not require sensors to detect rotor position or movement. Position and rotation can be controlled simply by sending pulse signals. This makes it easier to develop control programs and allows for simpler and more cost-effective control systems.

High torque at low speed

Stepper motors can rotate at low speeds while still delivering high torque. Other motor types often require gear mechanisms to achieve similar torque at low speed, but stepper motors can do so without gears, resulting in a more compact and simpler design.

High precision

Stepper motors respond quickly when starting and stopping. They have minimal angular errors and do not accumulate positioning errors over time.

Strong holding torque when stationary

Even when not energized, stepper motors can hold their position due to magnetic attraction between the rotor and stator teeth.

AC servo motors share some of these characteristics and offer additional capabilities. They are equipped with position detection components such as high-resolution encoders. Their rotors are designed with optimized inertia to enable fast response and stable rotation. They are driven by sine-wave current that corresponds to the position of the rotor. AC servo motors outperform stepper motors in several areas: they can generate stable torque across a wide speed range and automatically return to the correct position if any deviation occurs while stopped. However, they are more costly due to the need for high-resolution encoders and advanced drivers, and control systems using AC servo motors are also more costly and complex than stepper motors.

Stepper motor common applications: when should you use one?

Stepper motors are especially suitable for applications where:

- Precise positioning is critical

- Accuracy matters more than speed

- There is a need to balance performance with cost

Below are examples of products and systems where stepper motors are commonly used. However, these are just a few cases; stepper motors may also be applicable in many other scenarios depending on your design requirements.

Home appliances & residential equipment

| Air conditioners |

Louver control (opening/closing, wind direction adjustment) |

|---|---|

| Plumbing |

Valve actuation (opening/closing) |

| Window shutters |

Automatic opening/closing |

| Copiers and printers |

Paper feeding and sorting. Toner drum rotation |

| Stage/stadium lighting |

Light/projector panning and tilting |

Commercial equipment

| Vending machines |

Cup transport and bill feeding |

|---|---|

| ATMs |

Tray elevator driving, paper/bill feeding and sorting |

| Surveillance cameras |

Camera panning and tilting |

Industrial equipment

| Belt conveyors |

Roller driving |

|---|---|

| 3D printers |

Nozzle movement |

| Robotic arms |

Arm bending and rotation |

| Analyzers |

XY table movement |

| Machine tools |

Tool/nozzle positioning, material feeding |

| Semiconductor manufacturing equipment (SME) |

Stage/arm movement, tool/probe positioning |

Medical devices

| Dialysis machines |

Tube peristalsis |

|---|---|

| Syringe pumps |

Syringe pushing |

Research equipment

| Analytical instruments |

Sample stage movement/rotation/tilting, liquid dispensing, optical alignment, valve/pump control and detector scanning |

|---|

Space applications

| Gimbals |

Auto-tracking of pointing mechanism |

|---|---|

| Solar panels |

Deployment and sun tracking |

Stepper motor products and application mapping

The following table shows examples of how ASPINA stepper motors are used in various applications, categorized by product series.

| Application | ASPINA stepper motor product series | |||||||

|---|---|---|---|---|---|---|---|---|

| SST28D | SST35D | SST36C | SST42C | STA-42D | STA-56D | SST60D | SST86D | |

| Nozzle and ink head in 3D printers | Yes | |||||||

| Paper feeder and sorter (e.g., banknotes, copy paper) | Yes | Yes | ||||||

| Belt conveyor roller drive | Yes | Yes | Yes | Yes | Yes | |||

| Tool, nozzle and table in machine tools | Yes | Yes | Yes | Yes | Yes | Yes | ||

| Light and projector in stage/stadium lighting | Yes | Yes | Yes | |||||

| Syringe pump | Yes | Yes | Yes | Yes | Yes | |||

| Arm mechanism in robotic arms, etc. | Yes | Yes | Yes | |||||

| Louver in air conditioners | Yes | Yes | ||||||

| Solar panel in space satellites | Yes | Yes | Yes | Yes | ||||

| Valve actuator | Yes | Yes | Yes | Yes | ||||

| Surveillance camera | Yes | Yes | Yes | |||||

| Aperture such as antennas on space satellites | Yes | Yes | Yes | |||||

| Sample stage in SMEs or analyzers | Yes | Yes | Yes | |||||

ASPINA develops and manufactures stepper motors tailored to specific requirements, including environmental conditions and performance needs.

Limitations and considerations

Compared to other types of motors, stepper motors may lose positional accuracy when unexpected load variations occur. This is because they typically operate without position feedback from sensors or encoders. If the torque required to move the load exceeds the motor’s available torque, the rotor may lose synchronization with the input pulses, which may cause delayed motion or even complete stoppage.

Additionally, stepper motors generate damping vibrations during each step movement. These vibrations can lead to pulsation, which, when repeated intermittently, may cause mechanical vibration, reduced torque, and increased acoustic noise. These effects are particularly noticeable at low speeds or near the motor’s resonance frequency.

Technologies that help overcome stepper motor limitations

While stepper motors offer many advantages, there are also technologies that help mitigate their limitations and enhance their performance. For example, using a stepper motor with an encoder allows the system to monitor its operating status in real time. In addition to the inherent advantages of stepper motors such as high torque during rotation, movement and stopping, this setup enables precise monitoring and control of motor performance. Vibration, which can occur during step movements, can be reduced by adding mechanical dampers or applying microstepping drive techniques to stepper motors.

If you are concerned about the limitations of stepper motors or if you are experiencing issues in your application, it is a good idea to consult with a motor manufacturer for expert advice and potential solutions.

Overcoming your problems with stepper motors

ASPINA supplies not only standalone stepper motors, but also system products that incorporate drive and control systems as well as mechanical design. These are backed by comprehensive support that extends from prototyping to commercial production and after-sales service.

ASPINA can offer solutions that are tailored to suit the functions and performance demanded by a diverse range of industries, applications, and customer products, as well as your particular production arrangements.

ASPINA supports not only customers who already know their requirements or specifications, but also those who are facing problems at early stages of development.

Do you struggle with the following concerns?

Motor selection

- Don't have detailed specifications or design drawings yet, but need advice on motors?

- Don't have anyone in-house with expertise in motors and can't identify what sort of motor will work best for your new product?

Motor and associated component development

- Want to focus your resources on core technology, and outsource drive systems and motor development?

- Want to save the time and effort of redesigning existing mechanical components when replacing your motor?

Unique requirement

- Need a custom motor for your product, but been declined from your usual vendor?

- Can't find a motor that gives you the control you require, and about to give up hope?

Seeking answers to these problems? Contact ASPINA, we are here to help.

List of the same series columns

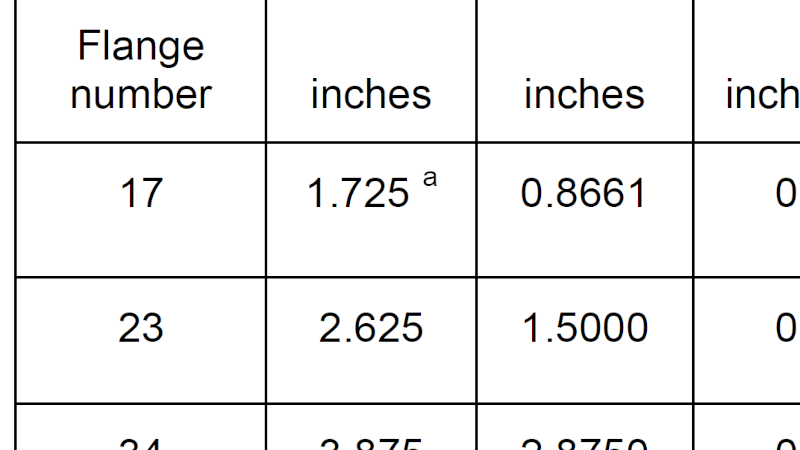

- NEMA stepper motor sizes chart and selection guide

- What is a brushless DC motor? What is the difference between brushless motor and brushed motor?

- What is a DC motor? - DC motor types, how they work, and how to control them

- Applications for blower motor

- What is a blower motor?

- Features and applications of DC motors

- Advantages of brushless DC motors over brushed DC motors

- Is this brushless motor cheap or expensive? - What factors determine its price?

- What is a geared brushless DC motor?

- How does an electronic speed controller for a brushless DC motor work? And what should you consider when you choose the right one?

- Small brushless motors

- What are the disadvantages of brushless DC motors? And how can they be overcome?

- Advantages of brushless DC motors: How they differ from brushed DC motors

- What is an actuator?

- Do brushless DC motors require a drive circuit? – Controlling brushless DC motors

- What is a stepper motor?

- What is an electric motor?

- How are stepper motors controlled? - Speed control of stepper motors

- How are DC motors controlled? - Speed control of DC motors

- Brushless DC motor applications: examples that demonstrate their features

- Stepper motor applications: Examples that demonstrate their features

- Motors designed for easy control: How do stepper motors work?

- What are the differences between brushed and brushless DC motors?

- What is a PSC motor

- What is a servo motor?

- What is a blower?

Related information

Contact us for more information

- New inquiry

- Prototype

- Upgrade

- Customization

- Your spec

- Literature

- Support

- Others