What is a PSC motor

-

Automation

-

Health & wellness

-

Life environment

-

Automotive

14 Sep. 2020

A Permanent Split Capacitor (PSC) Motor is a type of single-phase AC motor; more specifically, a type of split-phase induction motor in which the capacitor is permanently connected (as opposed to only being connected when starting).

AC motors can be divided into single- and three-phase motors depending on whether they are driven by a single*1- or three-phase*2 power supply.

A number of different types exist for single-phase induction motors. One of these involves using a capacitor*3 to generate a magnetic field in such a way that it simulates a second power supply phase, thereby generating the torque needed to start the motor rotating*4. Such motors are called "capacitor start motors" to reflect the use of a capacitor for this purpose. The category also includes motors in which the capacitor remains connected at all times (not just when starting) and these are called "capacitor run motors" or "permanent capacitor motors".

-

*1Single-phase: The type of power supply used in residential homes.

-

*2Three-phase: The type of power supply generated at power plants and supplied to factories and other industrial loads.

-

*3Capacitor: An electronic device that is able to accumulate and discharge electrical energy, also known historically as a condenser. An alternative design of single-phase induction motor that does not use a capacitor is the shaded-pole motor.

-

*4In addition to capacitor start motors, two other single-phase induction motor designs that do not require a capacitor to generate a starting torque are the split-phase induction motor and the shaded-pole motor.

How PSC motors work

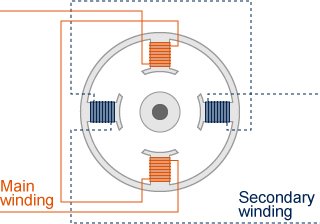

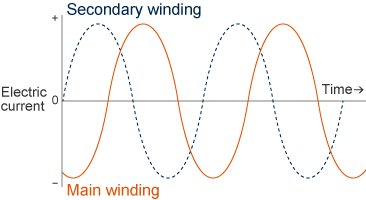

To use a single-phase power supply available in residential homes to drive a motor, there is a need for a mechanism to start the motor rotating. A PSC motor does this by having separate main and secondary windings (as shown in the diagram), with the main winding connected directly to the power supply and the secondary windings connected via a capacitor.

When the power supply is turned on, the current flows first in the main winding and then, with a short delay due to the capacitor, in the secondary winding. This difference in the main and secondary winding currents takes the form of a phase difference (meaning their waveforms are offset from one another on the time axis), causing the peak magnetic field to alternate between the two windings and thereby generating a torque that starts the motor rotation.

Background to development of PSC motors

One of the principles behind the single-phase induction motor (PSC motor) is the phenomenon of "Arago's rotations" discovered by François Arago in 1824. His discovery was that, when a magnet is rotated adjacent to a disk of non-magnetic material (a metal such as copper or aluminum that is not attracted by a magnet), the disk also starts to rotate along with the magnet.

At end of the 19th century, Nikola Tesla, recognized as one of the main proponents of the alternating current (AC) electricity system, invented the first practical induction motor and established the associated technologies, leading to the extensive uptake of AC motors in industry. The subsequent emergence of simple and low-cost single-phase induction motors that featured ease of use and compactness led to even more widespread use of these motors to power home appliances and other machinery in a variety of settings, including homes and small/medium scale factories.

Nowadays, however, electronically commutated (EC) motors have become commonplace in a wide range of fields, being both more efficient and easier to use than single-phase induction motors. These EC motors are commonly known as brushless direct current (BLDC) motors.

Comparison of PSC motor and EC motors

While capacitor motors are practical and easy to use, EC motors have come to be widely used in a diverse range of applications due to advantages that include superior energy efficiency and easier control of speed and other aspects of motor performance.

The following table lists the advantages and disadvantages of the two types of motor.

| PSC motors | EC motors | |

|---|---|---|

| Configuration | Simple |

More complex because of the need for a control module |

| Speed and torque | Difficult to control |

Easy to control with excellent operational characteristics in terms of ease and flexibility of speed and torque adjustment |

| Reliability |

As long-term use affects capacitor life, therefore maintenance is time-consuming |

Being brushless, can remain in use for a long time without maintenance |

| Efficiency |

Low efficiency due to energy losses from heat generated in capacitor |

Not only efficient, but the use of a controller reduces power consumption when off-peak |

| Response |

Speed adjustment is difficult with slow response |

Fast speed control response |

| Noise and vibration | High | Low |

| Cost | Low | High |

Applications for PSC motors and EC motors

While the ability of PSC motors to run on familiar single-phase power has led to their widespread use in areas like the common household, small scale factories and agriculture, the use of EC motors has increased in recent years.

Applications for EC motors include the following.

- Air conditioning

- Home appliances

- Water heaters and burner units

- Environmental equipment

- Bathroom products

- Vending machines

- Freezer and refrigerator display cabinets

- ATMs, bill change machines, foreign exchange machines, ticket vending machines

- Clean rooms

- Optical products

- Printers

- Copiers

- Healthcare equipment

- Commercial equipment

List of the same series columns

- What is a brushless DC motor? What is the difference between brushless motor and brushed motor?

- What is a DC motor? - DC motor types, how they work, and how to control them

- Applications for blower motor

- What is a blower motor?

- Features and applications of DC motors

- Advantages of brushless DC motors over brushed DC motors

- Is this brushless motor cheap or expensive? - What factors determine its price?

- What is a geared brushless DC motor?

- How does an electronic speed controller for a brushless DC motor work? And what should you consider when you choose the right one?

- Small brushless motors

- What are the disadvantages of brushless DC motors? And how can they be overcome?

- Advantages of brushless DC motors: How they differ from brushed DC motors

- What is an actuator?

- What is a stepper motor?

- What is an electric motor?

- How are stepper motors controlled? - Speed control of stepper motors

- How are DC motors controlled? - Speed control of DC motors

- Brushless DC motor applications: examples that demonstrate their features

- Stepper motor applications: Examples that demonstrate their features

- Motors designed for easy control: How do stepper motors work?

- What are the differences between brushed and brushless DC motors?

- What is a servo motor?

- What is a blower?

Related information

-

Accelerate product development: Rapid sampling and tailored solutions with ASPINA’s seat ventilation blowers

-

Zehnder revolutionizes indoor ventilation with ASPINA's DR-29312 motor

-

Comprehensive guide to medical device design

-

ASPINA's quiet medical-grade blower innovation revolutionizes CPAP therapy for sleep apnea sufferers

Contact us for more information

- New inquiry

- Prototype

- Upgrade

- Customization

- Your spec

- Literature

- Support

- Others