What is a blower?

-

Automation

-

Health & wellness

-

Life environment

-

Automotive

18 Jun. 2020

A blower is a device that pushes out gases by imparting energy to increase its pressure and speed.

They range from the large blowers found in applications such as production machinery and clean rooms, to the small blowers built into devices such as home appliances or personal computers, and are used to blow air for exhausting ventilation or cooling.

How blowers work

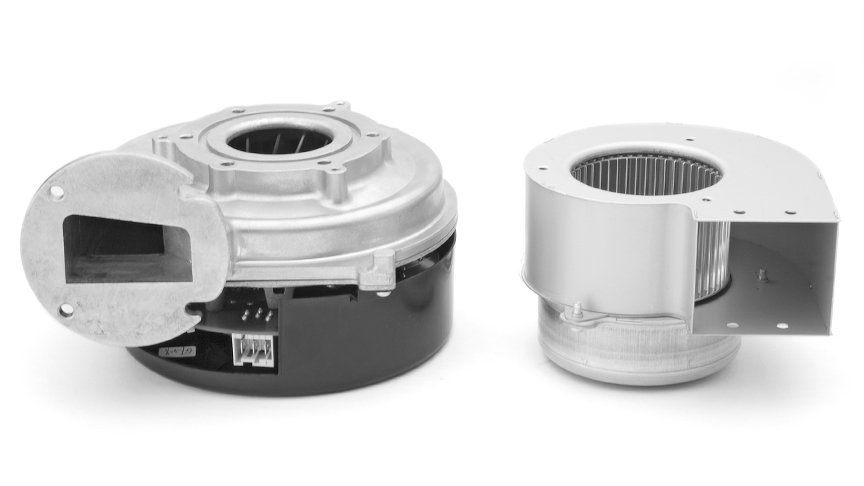

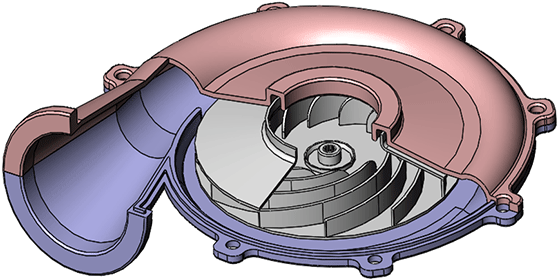

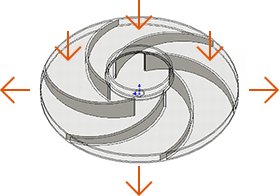

There are a variety of different types of blowers. The following example is of a brushless DC blower from ASPINA.

This blower is a centrifugal turbo type and is shaped like a snail shell. This blower contains a cylindrical impeller. The air is drawn in is pressurized by the centrifugal force imparted by the impeller rotation, and this pressurized air is then discharged.

History of blowers

Historically, among the very first blowers were the bellows used to supply air during the smelting of iron. Mentions of these bellows can be found in the literature of ancient Rome and China. Bellows were at first manually operated, then underwent various enhancements over time including the use of water power, evolving into an efficient means of supplying air.

In more recent times, the arrival of new power sources such as steam and electricity led to the development of a variety of other pneumatic (air-driven) equipment. Example applications include air brakes in steam locomotives and the opening and closing of automatic doors.

Nowadays, blowers and compressors used in various industries, and are built into equipment such as sorting or transportation machines, and processing or assembly, and packaging equipment. They are also found in products such as computers and home appliances, where they facilitate size reduction and performance enhancement.

Definition of blower

The American Society of Mechanical Engineers (ASME) defines the difference between compressors, blowers, and fans in terms of discharge pressure/suction pressure ratio as follows:

- Fans: Up to 1.11

- Blowers: 1.11 to 1.20

- Compressors: 1.20 or more

As you can see, blowers occupy the middle range between fans and compressors.

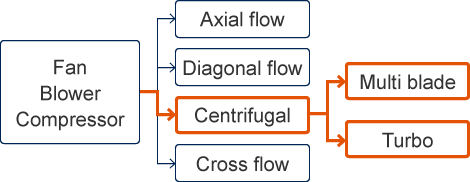

Types of blowers

While blowers come in many different types, ASPINA supplies centrifugal blowers; mainly multi blade or turbo types.

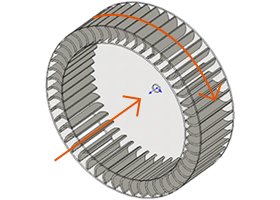

Multi blade type

The air flow is perpendicular to the axis of rotation, and the blades are typically angled forward in the direction of rotation. These types tend to be mid-range in terms of flow rate and pressure, and are used in applications such as duct ventilation, air conditioning, and cooling.

Turbo type

The air flow is perpendicular to the axis of rotation and the blades are typically angled backward with respect to the direction of rotation. These types tend to feature a low flow rate and high pressure, and are used in applications such as vacuum cleaners and dryers.

Uses for blowers

Example uses in building facilities and other equipment

- Air intake

- Air intake at manufacturing plants where machinery such as presses or welding machines are used

- Suction

- Suction to hold objects in place at food, textile, and other such manufacturing plants

- Vacuum gripping

- Suction for vacuum packing vegetables or to hold and lift paper or other processing materials

- Transportation

- Transportation in equipment such as pneumatic tubes or powdered material transporters

- Dust extraction

- Dust extraction at manufacturing plants where grinding is performed or powdered materials are used

- Ventilation

- Ventilation at worksites, trains, clean rooms, etc.

- Air supply

- Supply of air to gas burners, incinerators, or medical equipment

- Blowing

- Blowing for pipe cleaning, sandblasting, etc.

- Aeration

- Aeration of septic tanks or oxygen supply to aquaculture ponds

- Drying or cooling

- Drying or cooling processing materials on a production line

Example uses in commercial products

- Air brushes

- Vacuum cleaners

- Dryers

- Air conditioning

- Humidifiers

- Ventilation fans

- Water heaters

- Cutting plotters

- Copiers

- Printers

- 3D printers

- Air cleaners

- Telecommunication equipment

- Medical equipment

- Home fuel cells

- Automotive equipment

- Servers

- Personal computers

- Projectors

- Leaf blowers

Overcoming your problems with ASPINA's advanced blower technology

The key to blower development is to study the electric motor, fan, casing, circuitry, and other components in detail to build up an accurate understanding of where performance losses occur. ASPINA draws on their expertise built up through many years of blower development, not only to optimize fans and their motors and improve their performance, but also to make them smaller, lighter, have longer operating times, and able to run quietly with low vibration.

Along with providing greater flexibility in product design, ASPINA blowers can help reduce costs. ASPINA also has extensive scope for customization, so please don't hesitate to contact us.

List of the same series columns

- What is a brushless DC motor? What is the difference between brushless motor and brushed motor?

- What is a DC motor? - DC motor types, how they work, and how to control them

- Applications for blower motor

- What is a blower motor?

- Features and applications of DC motors

- Advantages of brushless DC motors over brushed DC motors

- Is this brushless motor cheap or expensive? - What factors determine its price?

- What is a geared brushless DC motor?

- How does an electronic speed controller for a brushless DC motor work? And what should you consider when you choose the right one?

- Small brushless motors

- What are the disadvantages of brushless DC motors? And how can they be overcome?

- Advantages of brushless DC motors: How they differ from brushed DC motors

- What is an actuator?

- What is a stepper motor?

- What is an electric motor?

- How are stepper motors controlled? - Speed control of stepper motors

- How are DC motors controlled? - Speed control of DC motors

- Brushless DC motor applications: examples that demonstrate their features

- Stepper motor applications: Examples that demonstrate their features

- Motors designed for easy control: How do stepper motors work?

- What are the differences between brushed and brushless DC motors?

- What is a PSC motor

- What is a servo motor?

Related information

-

Accelerate product development: Rapid sampling and tailored solutions with ASPINA’s seat ventilation blowers

-

Zehnder revolutionizes indoor ventilation with ASPINA's DR-29312 motor

-

Comprehensive guide to medical device design

-

ASPINA's quiet medical-grade blower innovation revolutionizes CPAP therapy for sleep apnea sufferers

Contact us for more information

- New inquiry

- Prototype

- Upgrade

- Customization

- Your spec

- Literature

- Support

- Others