Is this brushless motor cheap or expensive? - What factors determine its price?

-

Automation

-

Health & wellness

-

Life environment

-

Automotive

1 Feb. 2022

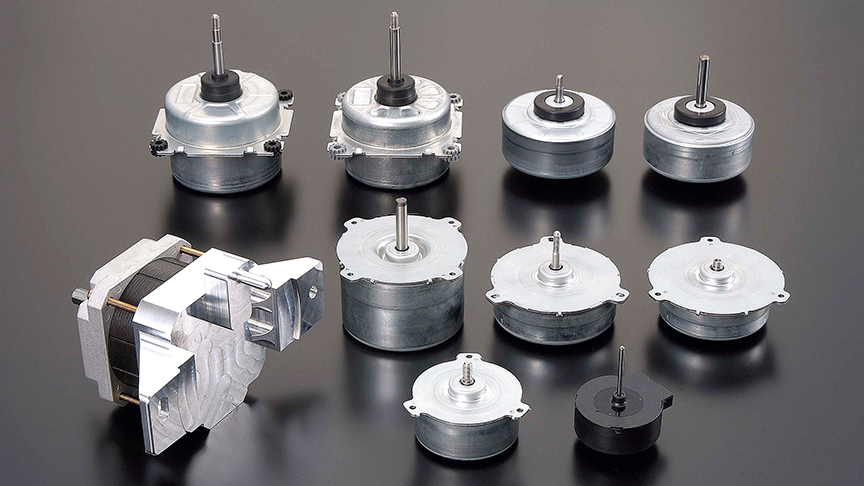

Performance is one of the factors that determine the price of brushless DC motors. While brushless DC motors benefit from longer life than their brushed counterparts (which use brushes and a commutator to provide an electrical connection and are therefore subject to wear), they also require a drive circuit to operate. In other words, there are performance and cost trade-offs between brushless and brushed DC motors.

Moreover, the prices of brushless DC motors themselves can vary widely. While reasonably priced brushless DC motors can be manufactured to suit particular performance requirements, there is nevertheless a limit to how much performance can be achieved using such brushless DC motors.

The price and performance capabilities of brushless DC motors depend on the parts and materials used

The price of a brushless DC motor depends on the parts and materials used. These also have a direct affect on available performance, and therefore on the price of the motor.

The table below lists typical performance and cost options for the main parts and materials used in brushless DC motors.

| Part or material | Type | Cost | Production cost | Motor performance (characteristics affected) |

|---|---|---|---|---|

| Rotor magnet | High performance | High | Fair | High (torque, etc.) |

| Low performance | Low | Fair | Low (torque, etc.) | |

| Electrical steel sheet | High grade | High | High | High (efficiency) |

| Low grade | Low | Fair | Low (efficiency) | |

| Rotor bearing | Ball bearing | High | High | High (long life, etc.) |

| Sleeve bearing | Low | Fair | Normal |

Rotor magnet

The two main types of rotor magnets are permanent and field magnets. As the characteristics of the magnet are among the factors influencing motor torque, the more efficient the magnet, the higher the performance of the motor. Unfortunately, equipping a brushless DC motor with better torque characteristics increases the cost of its parts and materials. Likewise, the use of lower-rated parts and materials reduces motor cost, but at the expense of reduced performance, limiting the scope of possible uses.

Electrical steel sheet

The two main components of an electric motor are its stator and rotor, with electrical steel sheet used as their core material. Different grades of electrical steel sheet result in different levels of motor efficiency.

While the use of low-grade steel keeps the materials and manufacturing (machining) costs down, it also results in less efficient motor performance. In contrast, motors made from high-grade electrical steel sheet can have very high performance. Unfortunately, this increases both materials and manufacturing costs.

Rotor bearing

The rotor shaft is supported by bearings. While a wide variety of bearings exist, rotor bearings are either ball bearings or sleeve bearings. Sleeve bearings can keep manufacturing costs low while still delivering products with adequate performance. When high performance is needed, on the other hand, such as in expensive models that require a long product life, this can be achieved by using brushless DC motors equipped with ball bearings.

Price, performance, parts for brushless DC motors

The prices of brushless DC motors vary depending on the material selection and design choices made to achieve the desired level of performance. In the case of the key components, the magnet, electrical steel sheet, and rotor bearings, there is a clear performance difference in terms of characteristics such as torque, speed, noise, efficiency, life, and reliability.

The parts and materials choices made for the magnet, electrical steel sheet, and rotor bearing are among the factors that will determine the performance and cost of the brushless DC motor.

The price and performance of a brushless DC motor depend on which considerations are given top priority. This is a question that arises time and again, as the quest for higher performance inevitably drives up the price. While it is important to balance price and performance, compromising on performance can be risky. The best way forward is to understand the different options for price, performance, and parts and materials so as to choose the motor that best suits the requirements.

List of the same series columns

- What is a brushless DC motor? What is the difference between brushless motor and brushed motor?

- What is a DC motor? - DC motor types, how they work, and how to control them

- Applications for blower motor

- What is a blower motor?

- Features and applications of DC motors

- Advantages of brushless DC motors over brushed DC motors

- What is a geared brushless DC motor?

- How does an electronic speed controller for a brushless DC motor work? And what should you consider when you choose the right one?

- Small brushless motors

- What are the disadvantages of brushless DC motors? And how can they be overcome?

- Advantages of brushless DC motors: How they differ from brushed DC motors

- What is an actuator?

- What is a stepper motor?

- What is an electric motor?

- How are stepper motors controlled? - Speed control of stepper motors

- How are DC motors controlled? - Speed control of DC motors

- Brushless DC motor applications: examples that demonstrate their features

- Stepper motor applications: Examples that demonstrate their features

- Motors designed for easy control: How do stepper motors work?

- What are the differences between brushed and brushless DC motors?

- What is a PSC motor

- What is a servo motor?

- What is a blower?

Related information

-

Accelerate product development: Rapid sampling and tailored solutions with ASPINA’s seat ventilation blowers

-

Zehnder revolutionizes indoor ventilation with ASPINA's DR-29312 motor

-

Comprehensive guide to medical device design

-

ASPINA's quiet medical-grade blower innovation revolutionizes CPAP therapy for sleep apnea sufferers

Contact us for more information

- New inquiry

- Prototype

- Upgrade

- Customization

- Your spec

- Literature

- Support

- Others