What is a stepper motor?

-

Automation

-

Health & wellness

-

Life environment

-

Automotive

24 Mar. 2021

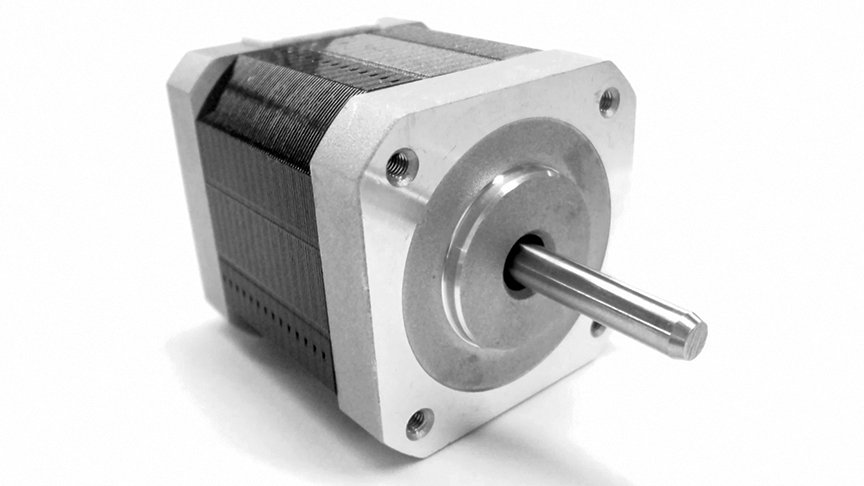

A stepper motor (also called a stepping motor) is one that rotates in an intermittent manner, moving by a fixed angle at each step rather than continuously rotating its shaft.

The movement of the second hand on a clock, for example, which advances one second at a time, could be achieved by using a stepper motor that moves in 6°increments, once every second.

So, how does a stepper motor achieve this characteristic of rotating its shaft by a fixed angle at each step?

The secret lies in the use of electrical pulses. A pulse is an electrical signal produced by turning a power supply on and off, with each such switching counting as one pulse. A stepper motor uses these pulses to achieve precise mechanical control over the angle and speed of rotation.

Types of stepper motors [1] (classified by rotor structure)

Stepper motors can be broadly grouped into the following three categories depending on the structure of their rotor.

- Permanent magnet (PM) motor

- The rotor contains a permanent magnet. A disadvantage of this structure is that it can not provide flexibility over the angle of rotation (step angle).

- Variable reluctance (VR) motor

- The rotor contains cores structured like the teeth of a gear. This allows for more flexibility in setting the step angle.

- Hybrid (HB) motor

- The rotor contains both permanent magnets and cores structured like the teeth of a gear. This type of motor is used in a wide variety of applications, combining the advantages of PM and VR motors. All of the stepper motors developed and manufactured by ASPINA are HB motors.

Operation principle of HB stepper motors

The rotor is designed with a cylindrical permanent magnet positioned between two cores, these being concentric to the motor shaft and offset by a half pitch from each other. The rotor rotates by a fixed step angle each time a pulse is input. As a two-phase HB stepper motor with a 1.8°step angle rotates by 1.8°for each pulse, it takes 360°/1.8°= 200 pulses to make one full rotation.

Types of stepper motors [2] (classified by current flow in coil)

Stepper motors can also be grouped into the following two categories based on electric current flow in the coil.

Unipolar motor

Current in a unipolar motor always flow through the coil windings in the same direction. While this keeps the associated control circuit simple, it produces less torque than a bipolar motor.

Bipolar motor

Current in a bipolar motor can flow through the coil windings in either direction. While this requires a more complex control circuit than a unipolar motor, it produces more torque.

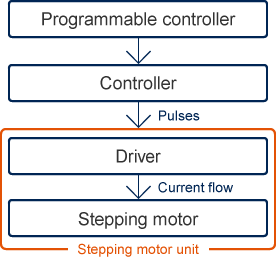

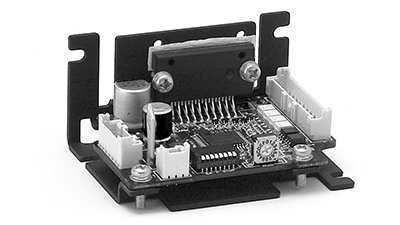

What is a stepper motor driver?

Stepper motors are used in conjunction with a driver circuit. The driver controls the angle and speed of motor rotation based on the input of electrical pulses from the controller.

Two-phase HB stepper motor driver

Two-phase HB stepper motor driver

Features of stepper motors

Stepper motors differ from other motor types in the following ways.

- Advantages

-

- As the angle of rotation is determined by the number of pulses (digital input), control of position (angle of rotation) is simple

- Can rotate at low speeds

- Can use open-loop (non-feedback) position control

- Excellent ability to remain locked in position when halted

- Disadvantages

-

- Requires a drive circuit

- Loss of synchronization can occur due to factors such as unexpected changes in load

- High level of vibration and noise

Applications for stepper motors

The excellent halting accuracy, high torque at medium and low speeds, and superior responsiveness of stepper motors means that they can be used in a wide range of drive applications that demand precise control.

- Production machinery

- Medical equipment

- Laboratory analytical instruments

- ATMs

- Vending machines

- Ticket vending machines

- Copiers

- Robots

- Optical disk drives (Blu-ray and DVD drives, etc.)

- Laser printers

- Digital cameras

- Air conditioning louvers

- Amusement machines

Overcoming your problems with stepper motors

ASPINA supplies not only standalone stepper motors, but also system products that incorporate drive and control systems as well as mechanical design. These are backed by comprehensive support that extends from prototyping to commercial production and after-sales service.

ASPINA can offer solutions that are tailored to suit the functions and performance demanded by a diverse range of industries, applications, and customer products, as well as your particular production arrangements.

ASPINA supports not only customers who already know their requirements or specifications, but also those who are facing problems at early stages of development.

Do you struggle with the following concerns?

- Motor selection

-

- Don't have detailed specifications or design drawings yet, but need advice on motors?

- Don't have anyone in-house with expertise in motors and can't identify what sort of motor will work best for your new product?

- Motor and associated component development

-

- Want to focus your resources on core technology, and outsource drive systems and motor development?

- Want to save the time and effort of redesigning existing mechanical components when replacing your motor?

- Unique requirement

-

- Need a custom motor for your product, but been declined from your usual vendor?

- Can't find a motor that gives you the control you require, and about to give up hope?

Seeking answers to these problems? Contact ASPINA, we’re here to help.

List of the same series columns

- What is a brushless DC motor? What is the difference between brushless motor and brushed motor?

- What is a DC motor? - DC motor types, how they work, and how to control them

- Applications for blower motor

- What is a blower motor?

- Features and applications of DC motors

- Advantages of brushless DC motors over brushed DC motors

- Is this brushless motor cheap or expensive? - What factors determine its price?

- What is a geared brushless DC motor?

- How does an electronic speed controller for a brushless DC motor work? And what should you consider when you choose the right one?

- Small brushless motors

- What are the disadvantages of brushless DC motors? And how can they be overcome?

- Advantages of brushless DC motors: How they differ from brushed DC motors

- What is an actuator?

- What is an electric motor?

- How are stepper motors controlled? - Speed control of stepper motors

- How are DC motors controlled? - Speed control of DC motors

- Brushless DC motor applications: examples that demonstrate their features

- Stepper motor applications: Examples that demonstrate their features

- Motors designed for easy control: How do stepper motors work?

- What are the differences between brushed and brushless DC motors?

- What is a PSC motor

- What is a servo motor?

- What is a blower?

Contact us for more information

- New inquiry

- Prototype

- Upgrade

- Customization

- Your spec

- Literature

- Support

- Others