How are DC motors controlled? - Speed control of DC motors

-

Automation

-

Health & wellness

-

Life environment

-

Automotive

11 Feb. 2021

The speed of a DC motor can be controlled by adjusting the voltage applied. This is because the speed and load torque of a DC motor is inversely proportional, and this translates with changes in drive voltage. Linear or PWM control can be used to vary the motor drive voltage, but PWM control has come to predominate in recent years due to its high efficiency.

This page will show step by step the relationship between speed, torque and drive voltage of a DC motor, and how to control it.

What is a DC motor?

First to begin with, an electric motor is a machine that uses electricity to turn a shaft, thereby converting electrical energy into mechanical energy. Electric motors are broadly divided into the following three types.

- DC motors

- AC motors

- Stepper motors

AC motors are driven by alternating current, and stepper motors are driven by pulses of electric power. DC motors on the other hand are powered by direct current, and have the following features.

- High starting torque and the ability to rotate at high speeds

- Motor performance is proportional to the applied voltage

For more information:

DC motors are further divided into brushed DC motors and brushless DC motors. Brushed DC motors have coils in their rotor, and alters the way current flows through the coils based on a mechanism using commutators and brushes. Brushed DC motors generate electrical and acoustic noise, and require frequent maintenance because their brushes and commutator are both consumable parts. But, they also feature a simple design and can operate without an electronic drive circuit if speed control is not needed.

A brushless DC motor, in contrast, avoids the need for a commutator and brushes by having a permanent magnet in the rotor. This, however, means they require a drive circuit. They also feature low maintenance, quiet operation, and long life.

For more information:

What is a DC motor? - DC motor types, how they work, and how to control them

Features and applications of DC motors

What are the differences between brushed and brushless DC motors?

Features of DC motors

Unlike AC motors, DC motors are very easy to use because of the ease with which their speed can be changed. So, how is this achieved in practice? The following explanation starts with looking at DC motor characteristics.

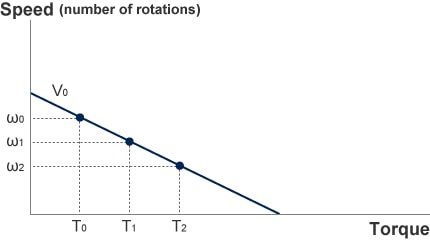

The characteristics of a DC motor are represented by a torque-speed curve that slopes downward to the right, with torque as the horizontal axis and speed as the vertical axis. The speed is highest when there is no load, falling away to the right until maximum torque is reached at zero speed.

The torque and speed vary with load as indicated by this torque-speed curve. Looking at the graph below, let’s consider a motor rotating at speed ω0 with torque T0. If the load torque then increases to T1, the motor speed will follow the torque down to the new speed of ω1. Likewise, if the load torque then further increases to T2, the speed falls to ω2.

DC motor torque and speed

DC motor torque and speed

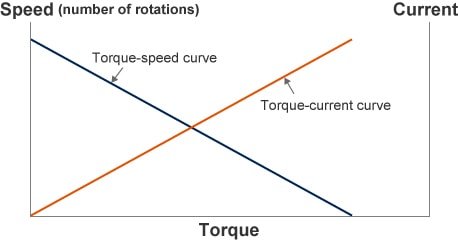

A look at the relationship between torque and current shows that these are proportional to one another. The ratio between the two is constant for a motor, with the relationship remaining the same regardless of changes in motor speed or drive voltage. This means that measuring the motor current on its own is enough to determine the motor torque.

DC motor torque-speed & torque-current curve

DC motor torque-speed & torque-current curve

What happens when the drive voltage is changed?

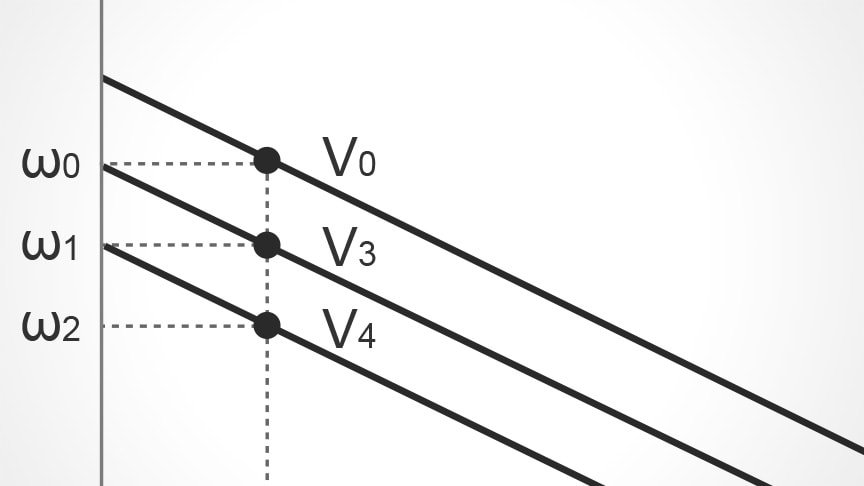

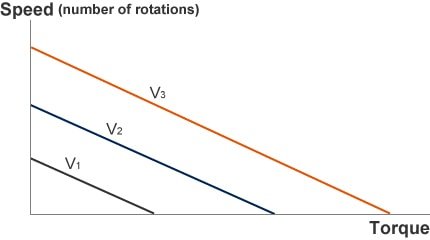

So, what happens to the torque-speed curve when the voltage used to drive the DC motor is changed? The graph below shows the torque-speed curves for different voltages. Doubling the drive voltage doubles both the no-load motor speed and the starting torque (torque when motor is locked in position). In other words, increasing the voltage shifts the torque-speed curve upward, parallelly. The torque-speed curve for a DC motor can be adjusted at will, by changing the voltage applied to the motor.

Motor drive voltage and torque curve

Motor drive voltage and torque curve

How to get a DC motor to rotate at a required speed

Now, given these characteristics, how can you rotate a motor at a required speed at any given load torque?

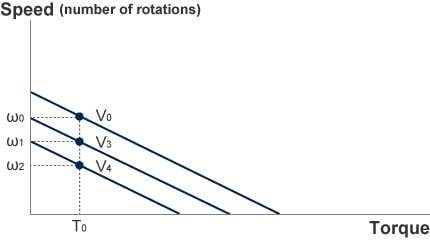

The torque-speed curve of a DC motor translates with changes in drive voltage. This means that the objective above can be achieved by simply adjusting the drive voltage. When looking at the graph below, if the requirement is to rotate at speed ω1 when the load torque is T0, for example, a drive voltage of V4 is too low, resulting in a speed of ω2. A drive voltage of V0 is too high, resulting in a speed of ω0. Driving the motor at the intermediate voltage of V3, however, is just right to achieve the desired speed of ω1.

Motor drive voltage and speed

Motor drive voltage and speed

By adjusting the drive voltage in this way, a DC motor can be made to rotate at a desired speed regardless of load torque.

Drive voltage control techniques

Two ways of adjusting the drive voltage are linear control and PWM control.

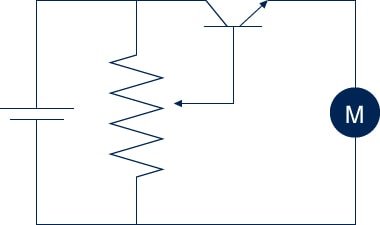

Linear control works by placing a variable resistor in series with the motor, and adjusting the resistance to vary the voltage across the motor. While a transistor or other semiconductor device can be used as the serial-connected variable resistor, this approach has poor efficiency due to the large amount of heat generated by the resistance (semiconductor), and therefore it is rarely used these days.

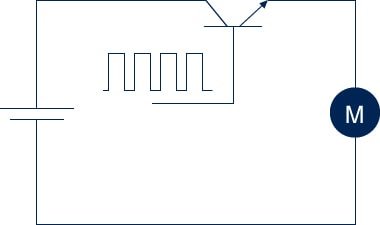

An alternative technique is the PWM control. The voltage applied to the motor can be varied by turning a semiconductor switch (such as a transistor or an FET) on and off at high speed, with the voltage being determined by the on and off pulse widths. The high efficiency of this technique makes it most commonly used nowadays.

Linear control

Linear control

PWM control

PWM control

Motor speed control

Use of these techniques allows the flexible adjustment of DC motor speed. However, additional control is required to keep a motor running at a constant speed. This is because the motor’s load torque varies due to the load itself, as well as other factors such as temperature, humidity, and changes over time. Simply driving the motor with a constant voltage will result in its speed fluctuating with changes in load.

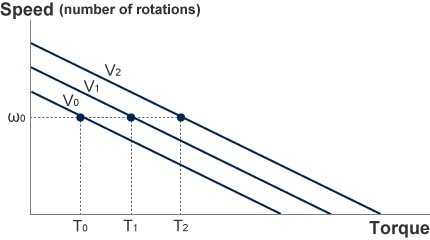

Maintaining a constant speed despite a variable load requires that the drive voltage be continually adjusted in response to these changes in load. The graph below shows an example where the load torque for a motor operating at a speed of ω0 reduces from T1 to T0, in which case reducing the drive voltage to V0 keeps the motor speed at ω0. If the torque instead increases to T2, maintaining a constant motor speed of ω0 requires that the drive voltage increase to V2.

Speed control

Speed control

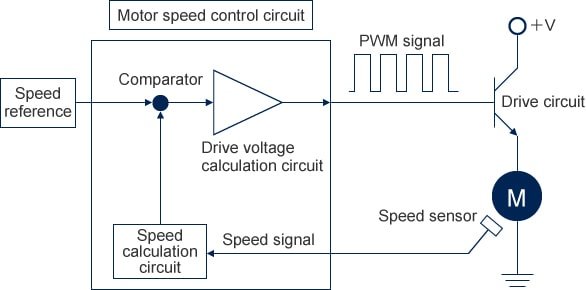

The speed is measured by a sensor attached to the motor. The difference between the measured and desired motor speed (speed error) is calculated, and the drive voltage is controlled in such a way that it is increased if the speed is too slow and reduced if the speed is too high. Doing this maintains a constant motor speed. While past practice was to use op amps or other analog circuits to control the drive voltage, the use of microcomputers has become the norm in recent years.

Circuit diagram of DC motor speed control

Speed control circuit for brushless DC motor

Speed control circuit for brushless DC motor

-

Speed sensor

Outputs a signal indicating the motor speed. Devices used for this purpose include Hall-effect sensors, encoders, and tachogenerators.

-

Speed detection circuit

Calculates the motor speed from the speed sensor signal.

-

Speed reference

Outputs the target motor speed.

-

Comparator

Calculates the difference between the speed reference and measured speed.

-

Drive voltage calculation circuit

Calculates the motor drive voltage based on the calculated speed error.

-

Drive circuit

A circuit that adjusts the voltage applied to the motor in accordance with the drive voltage signal.

A DC motor can achieve steady operation by controlling its speed to remain constant regardless of changes in load. These motors are also suitable for a wide variety of control practices that can be implemented using a microcomputer. DC motors find uses in many different applications that take advantage of their ease of control.

DC motors: Easy-to-use motors with simple speed adjustment

DC motors are powered by direct current, and, unlike AC motors, their speed is easy to adjust. The characteristics of a DC motor are represented by its torque-speed curve, in which speed and load torque are inversely proportional. This torque-speed curve translates with changes in drive voltage. Accordingly, by adjusting the voltage applied to a DC motor, it can be made to run at any speed regardless of load torque.

Linear or PWM control can be used to vary the motor drive voltage. PWM control has come to predominate in recent years due to its superior efficiency. PWM control varies the voltage by turning a semiconductor switch on and off at high speed in such a way that changing the on and off pulse widths changes the voltage.

Overcoming your problems with brushless DC motors

ASPINA supplies not only standalone brushless DC motors, but also system products that incorporate drive and control systems as well as mechanical design. These are backed by comprehensive support that extends from prototyping to commercial production and after-sales service.

ASPINA can offer solutions that are tailored to suit the functions and performance demanded by a diverse range of industries, applications, and customer products, as well as your particular production arrangements.

ASPINA supports not only customers who already know their requirements or specifications, but also those who are facing problems at early stages of development.Do you struggle with the following concerns?

- Motor selection

-

- Don't have detailed specifications or design drawings yet, but need advice on motors?

- Don't have anyone in-house with expertise in motors and can't identify what sort of motor will work best for your new product?

- Motor and associated component development

-

- Want to focus your resources on core technology, and outsource drive systems and motor development?

- Want to save the time and effort of redesigning existing mechanical components when replacing your motor?

- Unique requirement

-

- Need a custom motor for your product, but been declined from your usual vendor?

- Can't find a motor that gives you the control you require, and about to give up hope?

Contact ASPINA if you are interested in our BLDC motors.

List of the same series columns

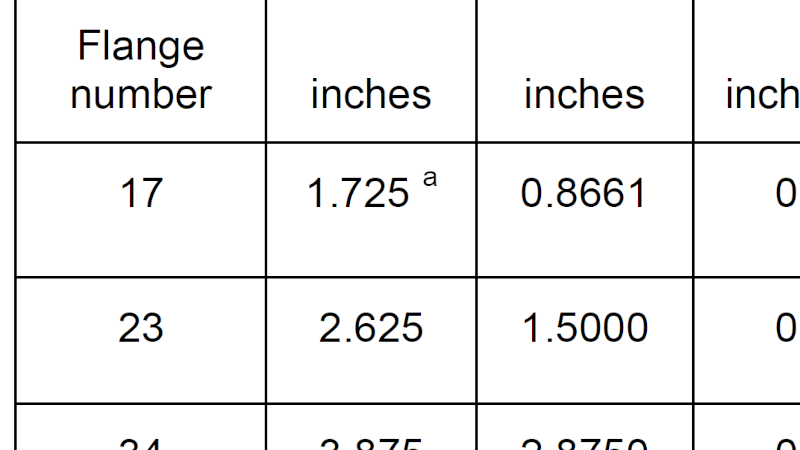

- NEMA17 stepper motor selection guide: Mounting dimensions, applications, selection and problem solving

- NEMA stepper motor sizes chart and selection guide

- What does a stepper motor do?

- What is a brushless DC motor? What is the difference between brushless motor and brushed motor?

- What is a DC motor? - DC motor types, how they work, and how to control them

- Applications for blower motor

- What is a blower motor?

- Features and applications of DC motors

- Advantages of brushless DC motors over brushed DC motors

- Is this brushless motor cheap or expensive? - What factors determine its price?

- What is a geared brushless DC motor?

- How does an electronic speed controller for a brushless DC motor work? And what should you consider when you choose the right one?

- Small brushless motors

- What are the disadvantages of brushless DC motors? And how can they be overcome?

- Advantages of brushless DC motors: How they differ from brushed DC motors

- What is an actuator?

- Do brushless DC motors require a drive circuit? – Controlling brushless DC motors

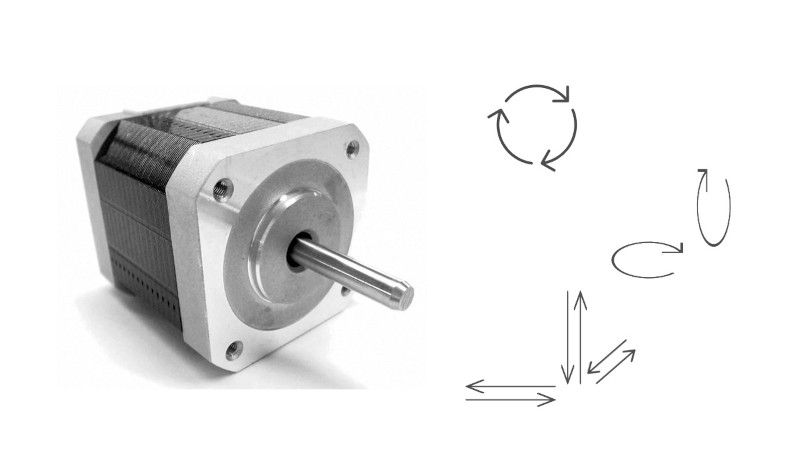

- What is a stepper motor?

- What is an electric motor?

- How are stepper motors controlled? - Speed control of stepper motors

- Brushless DC motor applications: examples that demonstrate their features

- Stepper motor applications: Examples that demonstrate their features

- Motors designed for easy control: How do stepper motors work?

- What are the differences between brushed and brushless DC motors?

- What is a PSC motor

- What is a servo motor?

- What is a blower?

Contact us for more information

- New inquiry

- Prototype

- Upgrade

- Customization

- Your spec

- Literature

- Support

- Others