Compactness & low vibration for comfort in patient's lifestyle - compressor

-

Health & wellness

-

Ventilator

-

Portable oxygen concentrator

Designing for use in medical devices emphasizing patient QOL

"We want you to build a medical compressor with low noise and vibration for use in ventilators."

When members of ASPINA's Medical Engineering (ME) Business Unit received this inquiry from an American startup company, they foresaw this as a new challenge for the company.

The recent rise in demand for in-home medical care has created a need for the development of a compact compressor with low noise and vibration for use in devices suited to this application. Since around 2012, ASPINA has been commercially supplying compressors for medical devices that feature low noise and vibration for use in oxygen enrichers (also known as oxygen concentrators), devices that take in air and then deliver it with an elevated oxygen concentration.

Impressed by the technical capabilities that had enabled ASPINA to build medical compressors with low noise and low vibration, the customer, a medical startup company looking to embark on development of a new product, inquired about developing a compressor for use in medical devices. The device that the company wanted to commercialize using ASPINA's compressor was a ventilator suitable for use in both hospitals and at home.

The medical sector places a high value on quality-of-life (QOL), with a growing consensus around the importance of providing patients with assistance that will help them achieve a life that better maintains their dignity. Ventilators suitable for use at both hospital and home play an important role in improving QOL. Accordingly, along with being compact enough to be portable, their performance requirements also include levels of noise and vibration that are low enough to avoid interfering with people's sleep when used in a bedroom.

ASPINA's medical compressor for use in oxygen enrichers used four cylinders to achieve low noise and vibration. The customer, who was on a first-time challenge to develop a ventilator, was confident that this compressor would also satisfy the specifications for a compact ventilator with low noise and vibration.

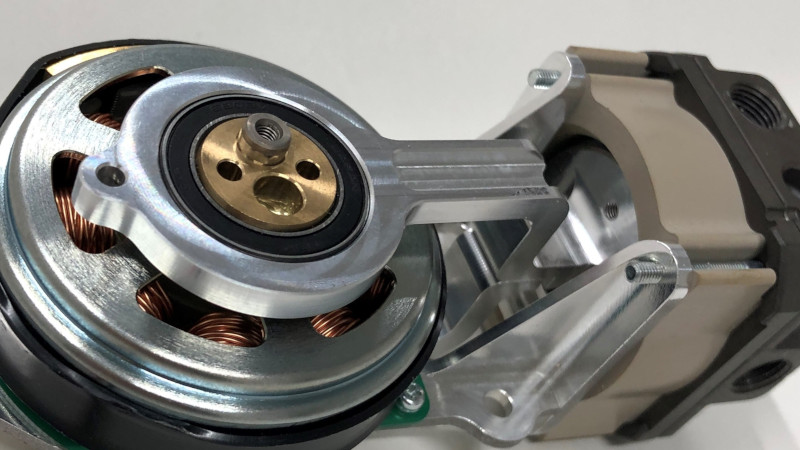

Four cylinders for low noise, integrated cooling fan for compact product size

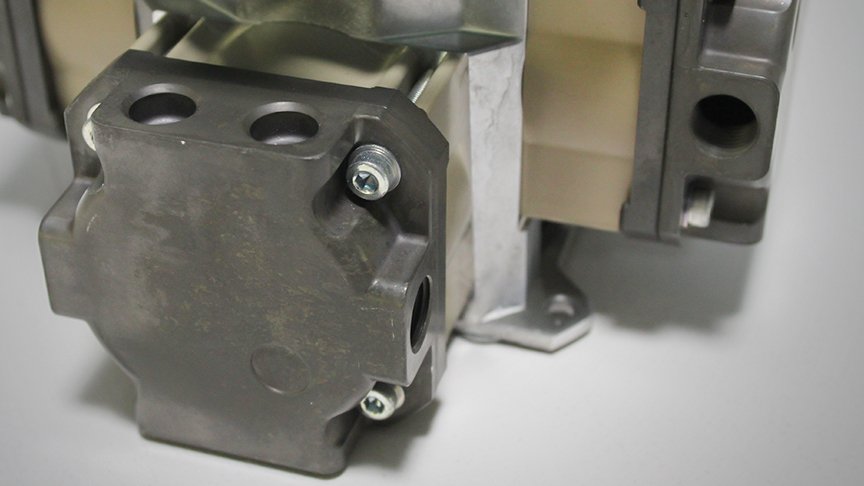

Most medical compressors at the time had only one or two cylinders. ASPINA, however, developed a new compressor with a four-cylinder design. This four-cylinder compressor pairs the cylinders and synchronizes their movement. The reciprocating motion of pistons in their cylinders being the causes of vibration and noise from a compressor, this cylinder pairing and synchronizing mechanism cancels out vibrations from one cylinder pair with the other, therefore suppressing noise and vibration. This design enabled the development of a medical compressor for oxygen enrichers that combined low noise and vibration with high output.

The customer set about studying whether this compressor for oxygen enrichers could also be used in their ventilator. What they discovered after installing the compressor in their new ventilator however, was that it produced more heat than they had expected when designing. The ventilator's cooling fan was unable to keep up with the heat being generated, causing the internal temperature of the device to rise.

The main sources of heat in the compressor are the coil and cylinders. This meant that efficient cooling of these two parts was needed to prevent the internal temperature of the ventilator from rising. On the other hand, given the limits on how large the ventilator could be while still being suitable for use at both hospital and home, having a cooling system that took up a large proportion of space inside the ventilator was not going to work.

ASPINA's solution was to incorporate a cooling fan onto the compressor itself. Not only did this provide direct cooling of the compressor, but it also reduced the overall size of the ventilator by eliminating the need for a separate fan in the device.

In order to seek an efficient cooling method, ASPINA built prototype fans in different sizes and shapes and conducted experiments to determine what type of fan to use and where to locate it for the best results. From this work, it was concluded that the most efficient arrangement was to locate the fan above the compressor motor, resulting in adopting a structural design in which air flows over the compressor from top to bottom.

ASPINA's compressor for medical equipment realizes low vibration, low noise, and downsizing of ventilator as a whole

ASPINA's compressor for medical equipment realizes low vibration, low noise, and downsizing of ventilator as a whole

ASPINA - Truly understanding customer needs in the medical device industry

ASPINA studies the true needs of customers thoroughly when developing their products. With the development of this compressor, ASPINA obtained advice from technical consultants on the current needs of the medical industry, and the issues associated with existing medical compressors. This led to the idea of using a four-cylinder design for the low-noise and vibration ventilator compressor.

ASPINA undertakes product development with the aim of delivering true customer value. In addition to making the compressor compact, the overall size of the ventilator was also reduced by incorporating the cooling fan for the compressor onto its body, thereby eliminating a separate cooling fan that would have been needed.

Contributing to the compactness of medical compressors

ASPINA intends to continue developing diverse products in response to market needs. The market for medical compressors indicates that, along with home care becoming more widespread, there is a need for a wide variety of product types. Recent times have seen an emerging demand for medical compressors that, along with featuring low noise and vibration, are also designed for portability. ASPINA has embarked on the development of medical compressors that meet this need.

With home care becoming more widespread, there is a need for a wide variety of product types

With home care becoming more widespread, there is a need for a wide variety of product types

One example is the development of medical compressors with fewer cylinders in response to the demand for small and light units that can be fitted into home-use medical devices that can be carried around. Requiring fewer parts brings the advantage of the devices being made smaller and lighter.

Links to related pages:

Exhibition information

-

5 Feb. 2025

-

21 Oct. 2024

-

15 Oct. 2024