Ideas that generate value for customers - ASPINA's patented technology

-

Automation

-

Robotics

Patents resulting from meeting customer needs based on knowledge of their industry

Innovative inventions are either the product of ideas never considered before or the product of new ways of doing things that previously nobody thought to try. Can novel insights be obtained? If so, is the technology available to realize them? Without the pursuit of ideas and technology, no new products would ever be developed. ASPINA has a track record of building an understanding of markets and of customers' needs, by then developing technology accordingly. The many different ideas and technologies that arise from this work are then embodied in patents.

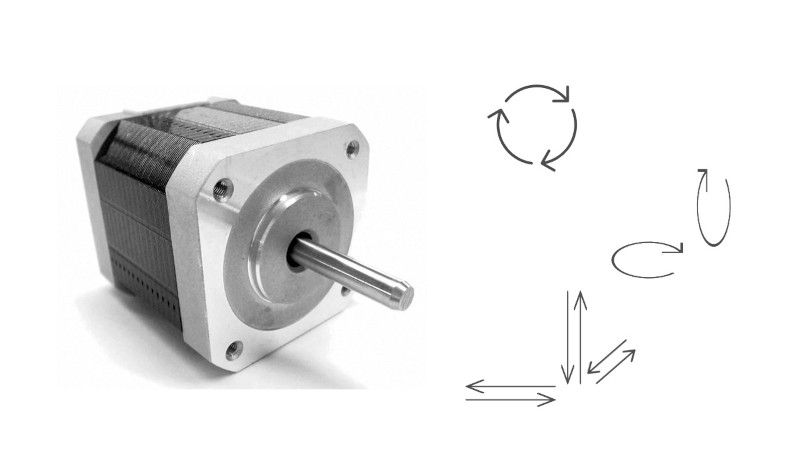

Electrically operated robot hands are one of the patented technologies successfully developed by ASPINA. These robot hands feature a hollow shaft design for multifunctionality as well as a cam-based hand mechanism and motor coupling designed to reduce overall unit size. Furthermore, behind each of these technical innovations lies a story of passion and ingenuity by their engineers.

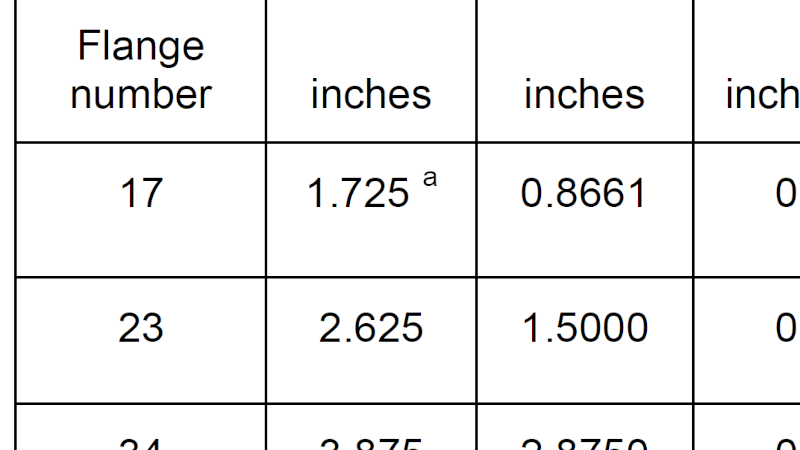

Hollow shaft design, a product of eliminated waste and continuous improvement

"Our goal was to be able to hold any kind of object." The robot hand inspired by this objective features two particular peculiarities. One is already patented, and ASPINA has applied to patent the other jointly with its corporate partner. The former, a hollow shaft design, is now a patented technology exclusive to ASPINA and provides an opening that runs right through the center of the shaft of the motor used to drive the cam, which in turn is used to move the fingers. This hole which extends all the way through the hand from back to front is a novel design and allows for the attachment of cameras and other devices (Japanese patent number 6342567).

This hollow shaft design can be used to provide robot hands with additional functionality. Using the opening provided by the hollow shaft to install a camera, for example, means that an object to be picked up can be viewed from the vantage point of the hand up to the time it is grasped. Similarly, an air attachment can be fitted to blow dirt off the object from above. Another option is to use in addition to the fingers a vacuum pad in order to enhance the strength of the hand to hold objects more firmly in place, when picking up objects.

An air attachment can be fitted in the opening to blow dirt off objects.

An air attachment can be fitted in the opening to blow dirt off objects.

However, the inclusion of the hollow shaft design required a complete redesign of the robot hand, with the elimination of unnecessary parts and changes to the internal mechanisms of the motor and to the control circuit.

Because the design had no precedent, development put a lot of work and effort into the mechanical design in order to satisfy the product requirements. After numerous changes to the design and improvements to the internal mechanisms and control techniques, the completed robot hand successfully attained the goal of combining a hollow shaft with small size. The final result was a useful new design for providing multifunctionality in electrically operated robot hands.

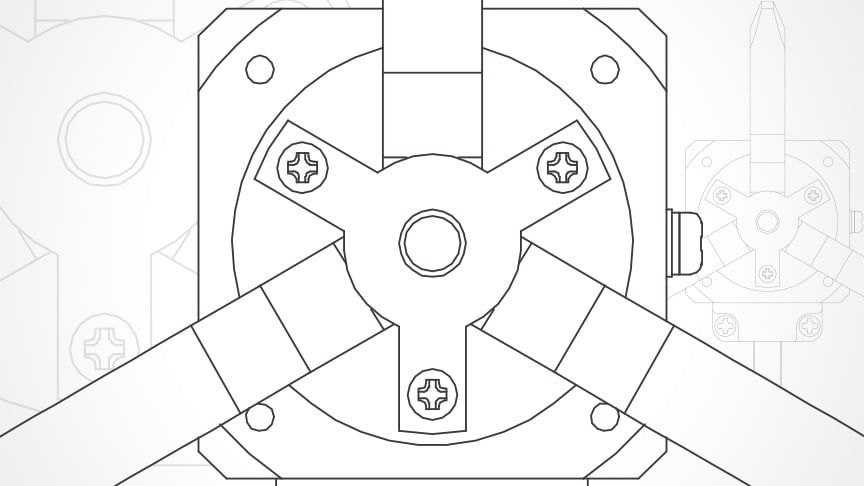

Partnership enables miniaturized coupling of cylindrical cam mechanism and motor

The second technical innovation was developed in partnership with another company to make the coupling of the cylindrical cam mechanism and of the motor smaller. The patent for this innovation is currently pending, with the two companies having filed a joint application (as of September 2019).

The cylindrical cam mechanism drives the joint which links the robot hand to its arm. Moreover, a coupling is needed that connects the cam to the motor shaft in a way that avoids interfering with finger movement. To realize this the cam mechanism needs to provide sufficient space.. It was recognized that a solution to this problem would be needed if robot arms were to be made smaller.

The space problem was resolved by adding an interconnecting threaded hole in the gap between the cams and a corresponding threaded hole for the motor shaft (Japanese unexamined patent application 2019-72795). The change in functional design succeeded in reducing the cost of the product itself and its maintenance by keeping the number of parts to be replaced to a minimum, as well as making the robot hand smaller and maximizing its grip strength.

Underpinning this success was the collaboration with a company that held patents on precision cylindrical cams. The idea that the development team came up with for building a robot hand that would be able to hold a wider variety of objects was to undertake the new development jointly with this partner, using the partner's cam mechanism as a base. The idea of reducing the size of the unit by combining ASPINA's motors and control technology with a cylindrical cam mechanism that had been patented by another company was a result of their wanting to develop a more advanced product. High-performance motors and control technology are products that only a motor manufacturer can deliver. This was the foundation that underpinned the success in taking the technology into the unfamiliar realm of a joint patent application.

Partnership with another company led to the success of making the robot hand smaller

Partnership with another company led to the success of making the robot hand smaller

What sort of future can be built on our patented technologies?

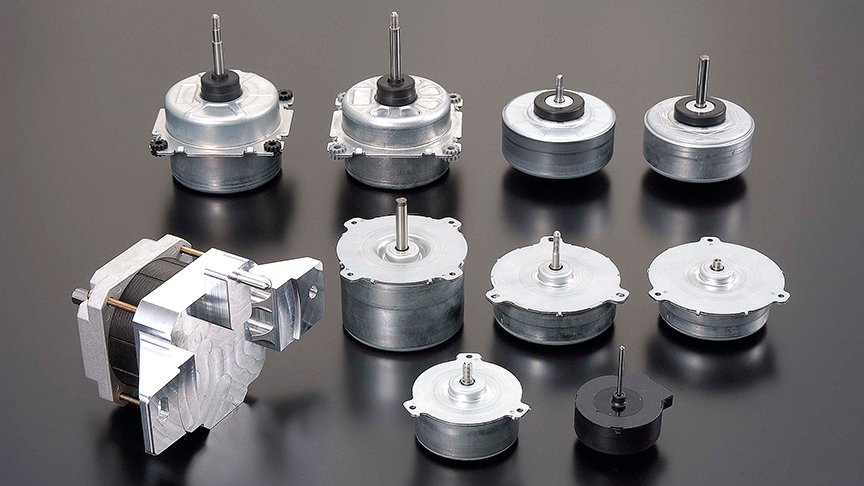

In addition to electrically operated robot hands, ASPINA products, such as motors, reducers, control circuits, fans, and cases, are equipped with novel and advanced technologies that create customer value.

These technologies have a special value which arises from the developers' spirit of inquiry and passion for satisfying both the market and the customer demands. So long as we, a leading motor manufacturer, continue to take up the many challenges on offer, there is no doubt that our portfolio of patented technologies will continue to expand.

Along with the endless testing and analysis work undertaken by the development teams, what has also been essential on our road to acquiring these patents, has been the enthusiasm and initiatives of many different people both inside and outside the company, including those that involved open innovation with corporate partners and university research institutions.

ASPINA intends to continue to offer new ideas and to develop advanced technical capabilities to solve the challenges faced by our customers. We will work with everyone involved to shape the future through patented technology.

Exhibition information

-

10 Oct. 2025