What is nearshoring?

-

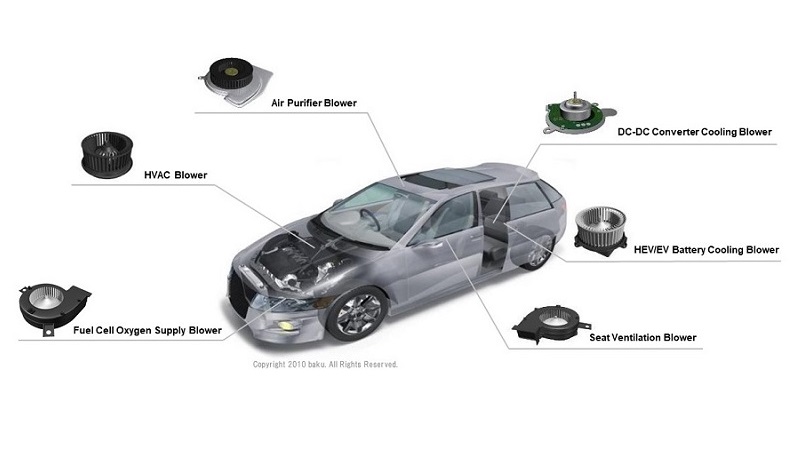

Automotive

-

Automotive seat ventilation system

31 Jan. 2024

- Definition of nearshoring

- Recent trends and events elevating nearshoring practices

- Difference between nearshoring and friend-shoring

- Advantages of nearshoring

- Industries most likely to benefit from nearshoring

- The most popular countries for nearshoring

- Nearshoring with ASPINA’s Mexico plant brings benefit to U.S. customers

Definition of nearshoring

Nearshoring is a business strategy that involves companies shifting their manufacturing and production operations closer to their main markets. Nearshoring involves outsourcing tasks to neighboring or nearby countries rather than distant offshore locations. It aims to reap the benefits of reduced costs and cultural alignment. This practice has gained popularity due to its potential to optimize operations and supply chains, particularly during times of crisis or disruption.

Recent trends and events elevating nearshoring practices

Nearshoring has gained traction as a strategy to mitigate the challenges of traditional offshoring. It offers benefits such as improved customer satisfaction, reduced transportation costs, and enhanced risk management. This approach builds more resilient and efficient supply chains in the face of global uncertainties.

Global supply chains have faced significant disruptions due to pandemics, wars, and extreme weather in recent years. The COVID-19 pandemic and associated lockdowns challenged global companies to procure components. Conflict between countries have led to increased spot fares and vessel evacuations, causing schedule disruptions. Drought in the Panama Canal has resulted in passage restrictions, leading to longer lead times. These events have underscored the importance of resilient and agile supply chains.

Difference between nearshoring and friend-shoring

Nearshoring and friend-shoring are two distinct approaches to managing global supply chains. Nearshoring involves the practice of locating manufacturing facilities in neighboring or nearby countries, often to reduce the time and costs associated with long-distance shipping and to respond more effectively to market changes. On the other hand, friend-shoring refers to the practice of sourcing from trusted, long-term suppliers, regardless of their location. This approach is used by companies that have strong relationships with their suppliers and are looking to ensure quality, reliability, and collaboration.

While nearshoring focuses on geographical proximity, friend-shoring emphasizes the strength of the relationship with the supplier, regardless of their location. Both approaches have their own set of benefits and challenges, and companies may choose one or the other based on their specific supply chain needs and strategic priorities.

Advantages of nearshoring

Nearshoring brings several benefits to companies, such as below:

- Cost savings

- Nearshoring to countries with lower labor costs can significantly reduce operational expenses and increase profitability. Also, companies can save transportation costs by shortening travel distance.

- Communication

- Geographic proximity and similar time zones make collaboration and communication between teams smoother and quicker. This can help overcome language or cultural barriers.

- Logistics

- With a shorter lead time, less inventory is in transit, and the easier it is to respond to customer demand in a timely manner.

- Quality

- Nearshoring can result in higher quality of products and services due to better control and efficiency.

- Talent pool

- By sending projects to another country, businesses can tap into a larger talent pool, reducing the risk of labor shortages and providing access to skilled workers when needed.

In summary, nearshoring offers a blend of cost benefits, smoother collaboration, improved logistics, higher quality, and access to a wider pool of talent. These advantages make attractive options for companies looking to optimize their operations and gain a competitive edge.

Industries most likely to benefit from nearshoring

Although many industries benefit from nearshoring, the industries below especially benefit from the enhanced efficiency and reduced costs, mitigating the challenges associated with offshoring, such as time zone differences, language barriers, and complex supply chains.

- Automotive

- The major automotive OEMs have introduced nearshoring, and leveraged it as a strategic move to meet the market's growing demand, particularly in the rise of electric vehicle (EV) technology.

- Manufacturing

- This industry is focused on efficient cost control, and nearshoring can reduce transportation costs, production costs and lead times, and supply chain risks.

- Information Technology (IT) and Software development

- Access to a skilled workforce and reduced time zone differences facilitates effective communication and collaboration needed for a streamlined and expeditious product development process.

- Customer Service and Support

- Nearshoring can help in reducing language barriers, ensuring cultural alignment, and fostering effective communication, leading to improved customer service.

- Healthcare and medical device manufacturing

- Nearshoring ensures efficient cost control and product/service quality maintenance, contributing to delivering safe and effective healthcare solutions to consumers.

The most popular countries for nearshoring

- Mexico

- The incentives provided through the USMCA have made it favorable for U.S. manufacturers to operate in Mexico. Its geographic proximity, lower costs, and increased efficiency have made it an attractive option for nearshoring, especially in sectors such as automotive, manufacturing, and IT.

- Eastern Europe

- Countries in Eastern Europe, such as Poland and Romania, are becoming increasingly popular particularly for western European countries. These countries retain a large pool of expert professionals and offer competitive costs.

- Central America

- Countries in Central America, such as Guatemala and El Salvador, are also leading the nearshoring boom. Their strategic location and shared border with the United States make them attractive destinations for nearshoring, particularly in the manufacturing and logistics sectors.

In summary, Mexico, Eastern Europe, and Central America are among the most popular destinations for nearshoring, offering diverse benefits such as geographic proximity, lower costs, and a skilled workforce.

Nearshoring with ASPINA’s Mexico plant brings benefit to U.S. customers

ASPINA’s Mexico plant supports U.S. customers by supplying products from Mexico.

Benefits of ASPINA’s Mexico plant for U.S. customers:

- Tariff free for specific products

- Low transportation cost

- Low inventory at customer’s warehouse

- Short lead-time

- High productivity

ASPINA, S.A. de C.V. (Mexico plant)

Avenida Río Mississippi 1043, Parque Technoindustrial Castro del Río, Irapuato, Guanajuato, C.P.36815 MÉXICO

If you have any questions or would like more information on our manufacturing plants or products etc., please feel free to contact us on our form.

Related information

-

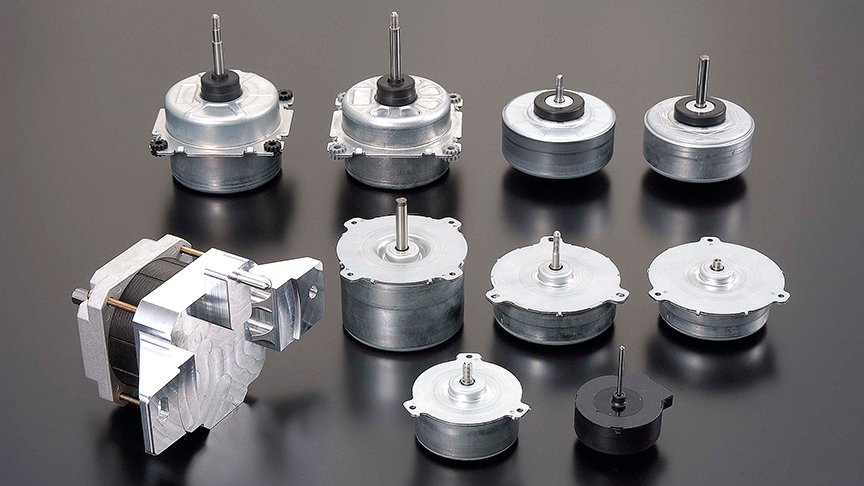

Accelerate product development: Rapid sampling and tailored solutions with ASPINA’s seat ventilation blowers

-

How to select automotive blower motor

-

What is a brushless DC motor? What is the difference between brushless motor and brushed motor?

-

Sleeve bearing development surpasses automotive industry standards – Automotive seat ventilation blower motor

Contact us for more information

- New inquiry

- Prototype

- Upgrade

- Customization

- Your spec

- Literature

- Support

- Others