Zehnder revolutionizes indoor ventilation with ASPINA's DR-29312 motor

-

Life environment

-

Residential ventilation unit

Zehnder: Indoor ventilation system manufacturer

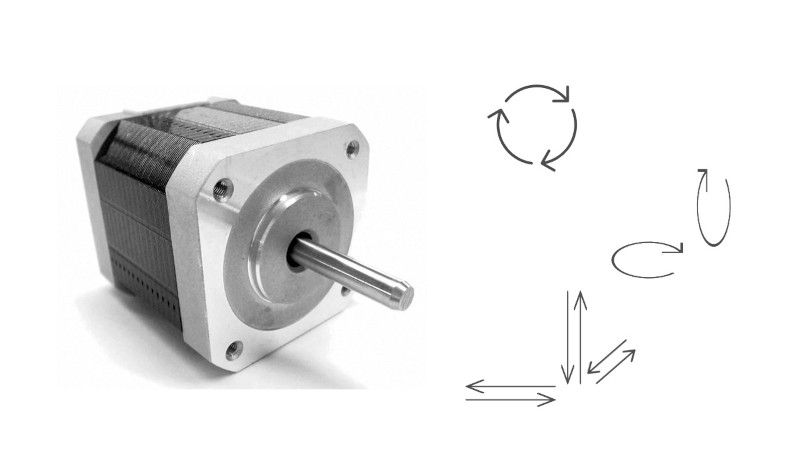

Zehnder Group, a leading developer and manufacturer of indoor ventilation solutions, faced a critical challenge: transitioning from traditional AC motors to Brushless DC (BLDC) motors to meet new requirements set by changes in U.K. Building Regulations. This case study explores how ASPINA’s DR-29312 motor became a key part of Zehnder’s innovative ventilation systems, ensuring compliance and improving performance.

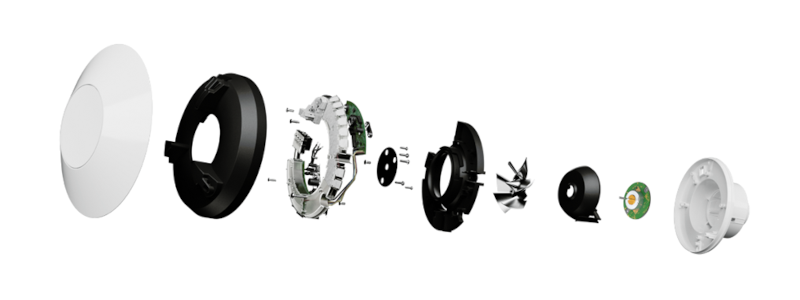

Exploded view of a Zehnder indoor ventilation unit with ASPINA DR-29312 brushless DC motor (the second component from the right) built-in

Exploded view of a Zehnder indoor ventilation unit with ASPINA DR-29312 brushless DC motor (the second component from the right) built-in

Overcoming technical hurdles with high-efficiency motors

The primary challenge for Zehnder was to replace their existing AC motors with high-efficiency BLDC motors to comply with upcoming government regulations. Integrating the new motor technology posed several challenges:

- Technical integration: Adapting the new BLDC motor to work seamlessly with existing systems required significant engineering adjustments.

- Performance optimization: Ensuring that the new motor met or exceeded the performance of the previous AC motors.

- Regulatory compliance: Achieving full compliance with stringent future government requirements.

ASPINA provided the DR-29312 motor, a high-efficiency BLDC motor that offers several advantages:

- Energy efficiency: Significantly reduced energy consumption compared to traditional AC motors.

- Enhanced performance: Superior performance metrics, ensuring reliable and efficient operation within Zehnder’s ventilation solutions.

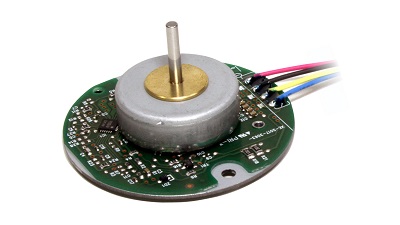

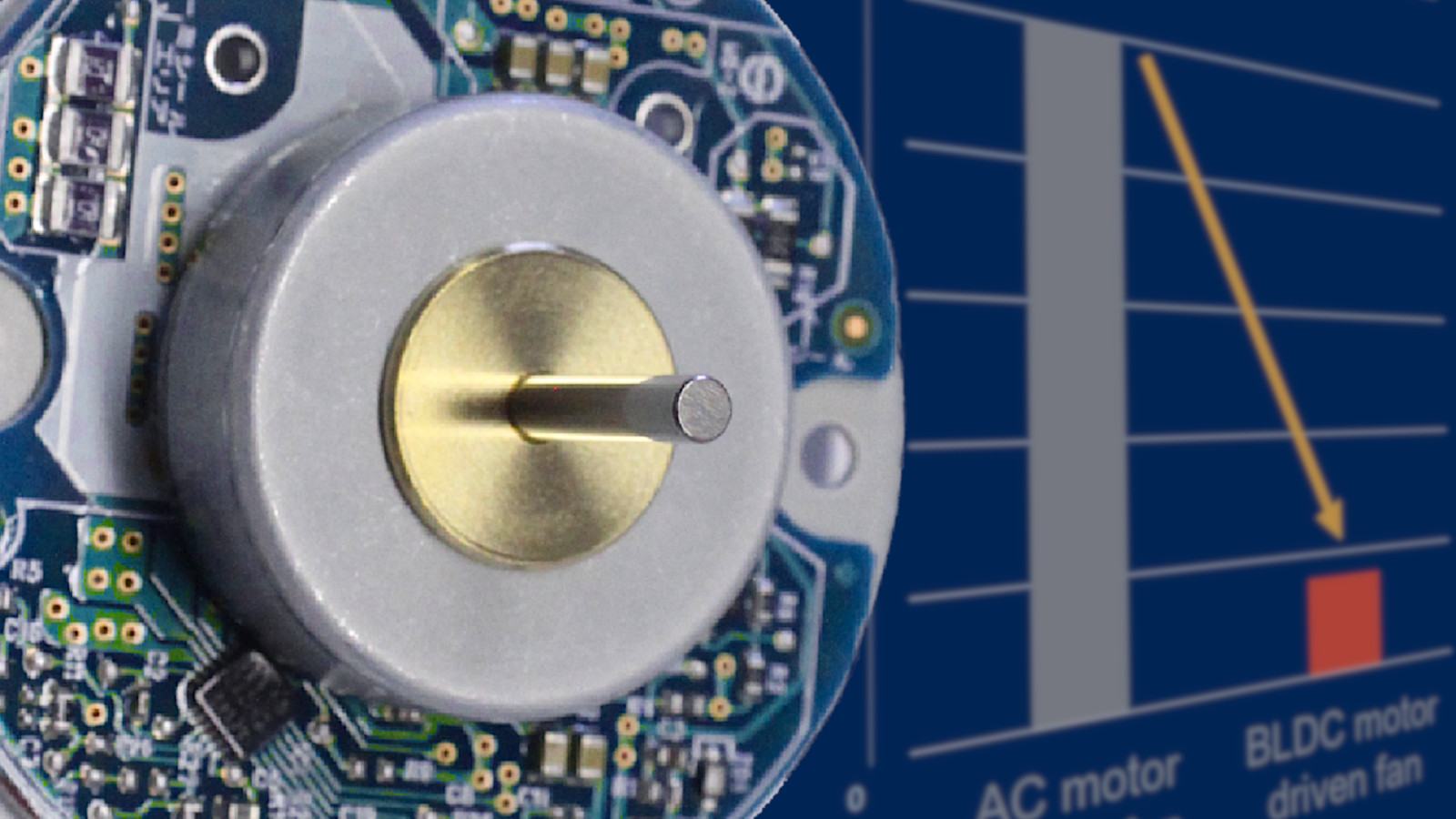

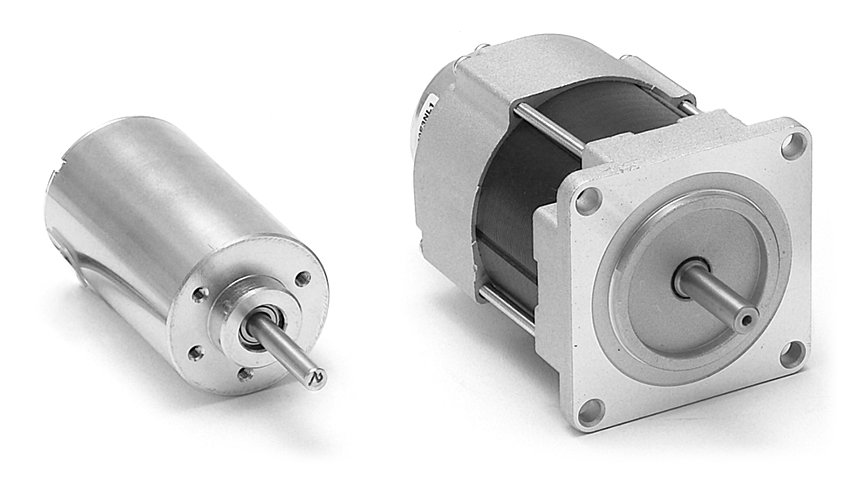

External view of ASPINA outer rotor brushless DC motor series - DR-29312, DR-24312

External view of ASPINA outer rotor brushless DC motor series - DR-29312, DR-24312

Implementation process: Ensuring seamless integration

The collaboration between Zehnder and ASPINA was marked by a series of biweekly meetings, fostering a strong relationship and ensuring seamless integration. Key steps included:

- Engineering collaboration: ASPINA’s engineers worked closely with Zehnder’s team to tailor the DR-29312 motor to their specific requirements.

- Rollout: The DR-29312 motors were successfully integrated into Unity CV2.1 and Unity CV3 models, ready for market deployment.

Benefits and customer feedback: Achieving compliance and performance goals

The integration of ASPINA’s DR-29312 motor yielded impressive results.

Zehnder praised the collaboration with ASPINA, highlighting the strong relationship developed through regular biweekly meetings. These meetings were crucial for addressing challenges promptly and planning the next steps effectively. The feedback underscored ASPINA’s commitment to customer success and innovation.

By integrating ASPINA’s DR-29312 motor, Zehnder not only met stringent government requirements but also enhanced the efficiency and performance of their indoor ventilation systems. This case study demonstrates the value of strategic partnerships and the impact of innovative technologies in driving industry advancements.

Discover how ASPINA’s advanced motor technologies can elevate your products. Feel free to contact ASPINA for more information.

Related information

Customer challenges

- Technical Integration: Adapting BLDC motors to existing systems.

- Performance Optimization: Matching or exceeding AC motor performance.

- Regulatory Compliance: Meeting new U.K. Building Regulations.

ASPINA solutions

- Energy Efficiency: DR-29312 motor reduces energy consumption.

- Enhanced Performance: Superior performance and reliability.

- Collaboration: Close engineering support and biweekly meetings.

- Seamless Integration: Successful deployment in Unity CV2.1 and Unity CV3 models.

Exhibition information

-

10 Oct. 2025

Related information

Contact us for more information

- New inquiry

- Prototype

- Upgrade

- Customization

- Your spec

- Literature

- Support

- Others