ASPINA's quiet medical-grade blower innovation revolutionizes CPAP therapy for sleep apnea sufferers

-

Health & wellness

-

CPAP

H Corporation: Leading medical device manufacturer

Challenges in developing an in-house blower for next-gen CPAP machines

ASPINA's medical device blowers are designed and optimized for quietness. In this case study, we explore how our blower was adopted for the next-generation compact CPAP (Continuous Positive Airway Pressure) machine by H Corporation, a leading medical device manufacturer.

CPAP therapy is considered the gold standard treatment for Sleep Apnea Syndrome (SAS). Since CPAP machines are used during sleep, quiet operation is crucial to avoid disturbing the user and their families. Recognizing the growing demand and competition, H Corporation aimed to develop a quieter, next-generation compact CPAP machine.

Initially, H Corporation tried to develop and produce the blower internally but faced significant challenges. The primary issue was the unstable quality of their blower. The motor, a critical component, did not operate consistently. Since the motor was sourced from another manufacturer, H Corporation couldn't make necessary improvements. Additionally, the manual balancing process resulted in inconsistent quality. Consequently, the assembled blowers had excessive noise and vibration, making them unsuitable for their new CPAP machine.

Moreover, H Corporation’s factory lacked the capacity for mass production. Limited space and imprecise design hindered their efforts. These limitations made it clear that their internally developed blower couldn’t meet the high standards required for their next-gen CPAP machine.

Exploring alternative CPAP blowers

To address the noise issues, H Corporation began evaluating blowers from other manufacturers. They tested several samples but found the noise levels to be unacceptably high. When they contacted the manufacturers, they learned that the motors causing the noise were not developed in-house, leaving no room for improvement or technical support.

During this challenging period, H Corporation discovered ASPINA at a medical device tradeshow. Impressed by the demonstration of ASPINA's blower, they requested a sample for evaluation.

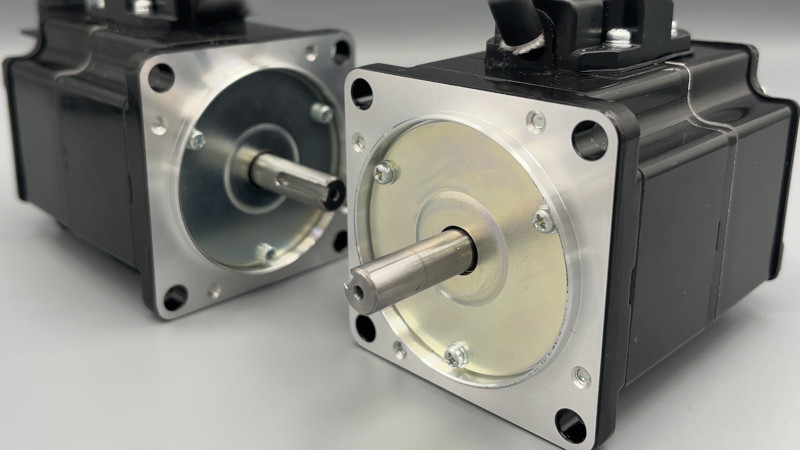

ASPINA 5kPa blower for medical devices

ASPINA 5kPa blower for medical devices

Collaboration with ASPINA to resolve noise issues

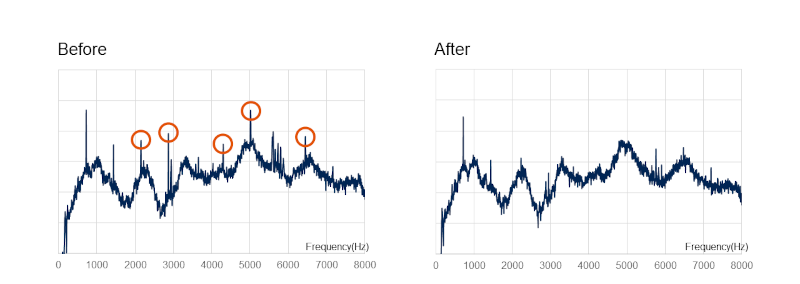

Upon receiving a sample blower from ASPINA, H Corporation conducted internal tests and found the blower to be exceptionally quiet. They were impressed by the noise reduction features, particularly in the motor and impeller, which are the primary noise sources. As a motor manufacturer, ASPINA had implemented innovative noise reduction techniques, addressing not only noise levels but also frequency, demonstrating a deep understanding of user needs. Consequently, H Corporation decided to integrate ASPINA’s blower into their CPAP machine.

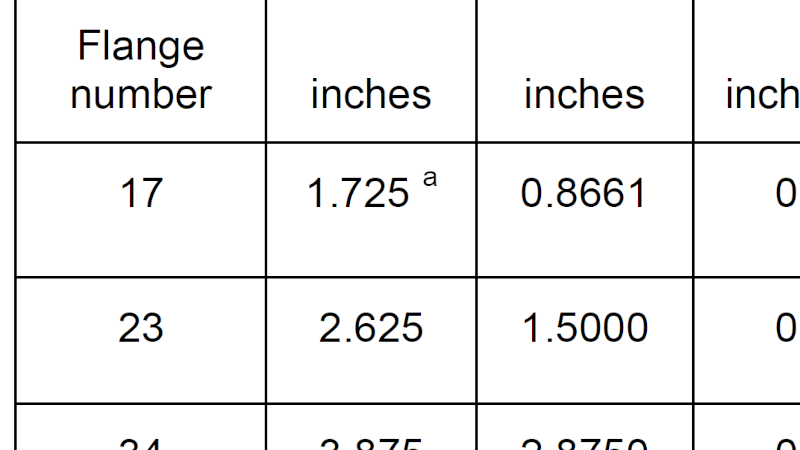

Example of frequency spectra before and after countermeasure made to address blower acoustic noise issue

Example of frequency spectra before and after countermeasure made to address blower acoustic noise issue

However, during prototype development, H Corporation encountered persistent acoustic noise issues. Suspecting the blower might be the source, they contacted ASPINA for assistance. ASPINA meticulously explained the potential noise sources, including blower noise, vibration-induced noise transmitted through the CPAP machine, and air noise from compressed air pipes. ASPINA also suggested countermeasures for each noise type.

To further investigate, H Corporation brought the blower assembly, including the surrounding mechanisms, to ASPINA’s development facility. Joint testing in ASPINA’s anechoic chamber revealed that redesigning the blower box could significantly reduce noise levels. Following ASPINA's recommendations, H Corporation adopted the newly designed blower box. The result was a substantial reduction in noise, successfully resolving the issue.

Comprehensive CPAP business support from ASPINA

ASPINA, with its global business operations, provided weekly meetings with H Corporation to address and resolve various challenges. The blowers were manufactured in a factory close to H Corporation’s designated delivery location, offering significant advantages in delivery times and logistics costs. This comprehensive support, from technical assistance during the product development phase to efficient supply chain solutions, maximized the value for H Corporation.

ASPINA Mexico factory manufactures and delivers products mainly for North America market.

ASPINA Mexico factory manufactures and delivers products mainly for North America market.

With ASPINA's support, H Corporation successfully completed the development and launched their next-generation CPAP machine. ASPINA’s after-sales support also promptly addressed any quality feedback from the market, ensuring continuous improvement and customer satisfaction.

ASPINA’s commitment to not only supplying blowers but actively solving problems made us an indispensable partner for H Corporation. Our 5kPa and 10kPa blowers, driven by advanced motor technology, are designed to meet the specific needs of the medical device market. From design and production to after-sales service, ASPINA offers precise solutions tailored to your requirements. If you face any challenges in medical device development, please do not hesitate to contact us.

Related information

Customer challenges

- H Corporation faced unstable quality with their internally developed blower for a new CPAP machine, with inconsistent motor operation and excessive noise.

- H Corporation’s factory lacked the capacity and precision to mass-produce the blowers.

- Alternative blower manufacturers couldn’t improve the acoustic noise from their blowers because the motors were outsourced.

ASPINA solutions

- ASPINA provided a small, quiet blower with consistent, high-quality performance, addressing the noise and vibration issues.

- ASPINA offered technical support, including joint testing and redesign recommendations, resulting in a quieter blower box and improved CPAP machine performance.

- From production to after-sales, ASPINA offered comprehensive support to maximize the customer value throughout their product lifecycle.

Exhibition information

-

10 Oct. 2025

Related information

Contact us for more information

- New inquiry

- Prototype

- Upgrade

- Customization

- Your spec

- Literature

- Support

- Others