HVAC blower motor

-

Automotive

-

Automotive HVAC system

10 Apr. 2023

What is a HVAC blower motor?

HVAC (Heating, Ventilation, and Air Conditioning) blower motors are the main components of air conditioning systems that send heated or cooled air into homes, offices, cars, etc.

Types of motor used in HVAC blower motors

The many different types of electronic motors can be broadly grouped into the following three categories based on their internal design and how they work.

- DC motors (powered by direct current)

- AC motors (powered by alternating current)

- Stepper motors (motors that rotate one step at a time in response to electrical pulses)

Two features that distinguish DC motors from the other two types are their high starting torque and ability to run at high speed. Typically, HVAC blower motors use AC or DC motors for their core. This page will focus on HVAC blower motors using a DC motor.

In order to understand the characteristics of a HVAC blower motor using a DC motor, we must first understand the characteristics of the DC motor itself.

DC motors can be divided into brushed and brushless DC motors

DC motors are divided into two categories depending upon whether they use brushes and commutators. DC motors that use brushes and commutators are called brushed DC motors, while those that use an electronic circuit instead are called brushless DC (BLDC) motors.

Differences between brushed and brushless DC motors

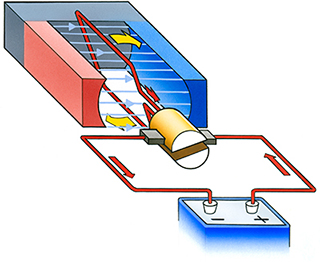

Principle of operation of a brushed DC motor

Brushed DC motors have their coil windings in the rotor. As the rotor rotates, the brush connections switch between commutators, thereby switching the flow of electrical current through each coil. By switching the direction of electrical current flow at appropriate times, the rotor can rotate continuously.

Principle of operation of a brushless DC motor

A brushless DC motor avoids the need for a commutator and brushes by having its permanent magnets in the rotor. Rotation of the rotor is maintained by detecting the position of the rotor magnetic poles and switching the electric current flow through the coils accordingly. For this reason, a brushless DC motor requires a driver (an electronic drive circuit). The detection of rotor shaft position, meanwhile, is done using a hall effect sensor or other magnetic sensors (although sensor-less motors also exist that can work without such a sensor).

Hall effect sensors uses the hall effect to determine magnetic field strength. By converting this into an electrical signal, the driver can detect the position of the permanent magnet (the orientation of its north and south poles) and switches the electric current flow through its coils in such a way that it keeps the motor shaft rotating.

Advantages of HVAC blower motors that use a brushless DC motor

HVAC blower motors that use brushless DC motors have several advantages over those that use brushed DC motors. The three main advantages are as follows.

Long life and low noise

A problem with HVAC blower motors that use brushed DC motors is the wearing of the brushes and commutator, which are in constant contact. In some cases, abrasion of the brushes is also a source of dust or sparking.

No such wear occurs with HVAC blower motors that use brushless DC motors as they lack this mechanical contact. Furthermore, as the absence of abrasion dust or sludge prolongs the motor life, it helps reduce the frequency of maintenance for routine motor replacement. Choosing brushless DC motors for blower motors in critical equipment extends its product life and avoids motor-related defects.

The characteristic scraping sound produced by brushed motors as the brushes rub against the commutator may be the result of resonance between parts or audible noise due to their rubbing against each other, sound produced by vibration or other movement in the rotor thrust direction, wind noise if the rotor has a built-in fan, or electromagnetic humming due to magnetic forces causing the stator core to vibrate.

Low electromagnetic noise

EMC considerations play an important role in part selection when you design a product.

HVAC blower motors using brushed DC motors tend to generate noise due to the significant sparking that occurs at each switching of contact between the brushes and commutator. Noise is a form of electromagnetic energy, just like other electrical signals. In the absence of appropriate control measures, it can interfere with other devices or electronic components, causing mis-operation or degraded performance.

On the other hand, the motor current of brushless DC motors can be controlled electronically. As this tends to result in less electromagnetic noise, HVAC blower motors using brushless DC motors are recognized as providing better conversion efficiency than ones using brushed DC motors, with lower levels of energy loss and noise.

Potential for energy saving

The weight of individual parts is an important factor in reducing the overall weight of a HVAC blower motor.

Because they do not require a brush assembly, the design of brushless DC motors is inherently more flexible, providing scope for reducing their size and weight. Furthermore, the smaller the parts of the motor, the less energy is needed to rotate it.

Given that power consumption by electric motors is estimated to account for 40 to 50% of global electricity use, a higher conversion efficiency (meaning less electricity is required to deliver a given amount of rotational energy) also helps reduce the load on the environment.

The features of brushless DC motors, which include long life, ease of control, and low electromagnetic noise, are essential to ensuring reliable HVAC blower motor control.

The overall impact that HVAC blower motors and the products they are used in have on the environment is also reduced by using motors that do not contain any lead, hexavalent chromium, or other materials restricted by environmental standards such as RoHS.

The trend of using brushless DC motors in HVAC blower motors

In recent years, the excellent efficiency and low noise of brushless DC motors have led to the expansion of their use in applications such as electrical products and precision machinery. Beyond home appliances and precision equipment, the automotive industry has developed a wide range of systems that incorporate brushless DC motors. Due to the latest trends such as the shift to electric vehicles and higher interest toward sustainability, more manufacturers are choosing brushless DC motors to benefit from their compact, light, and quiet features.

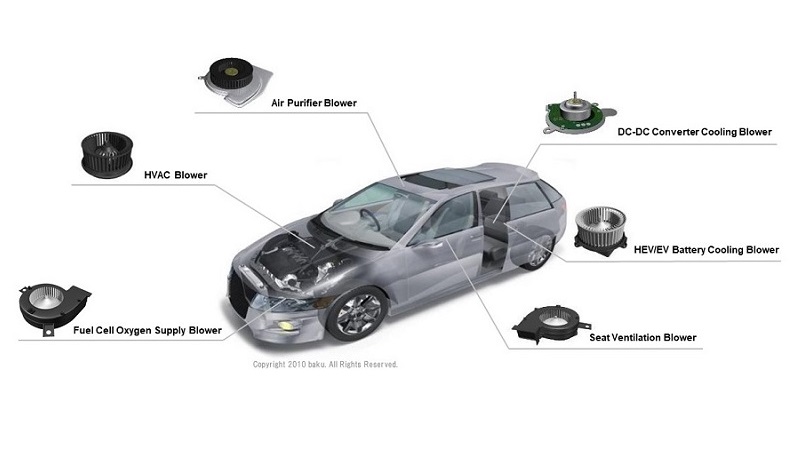

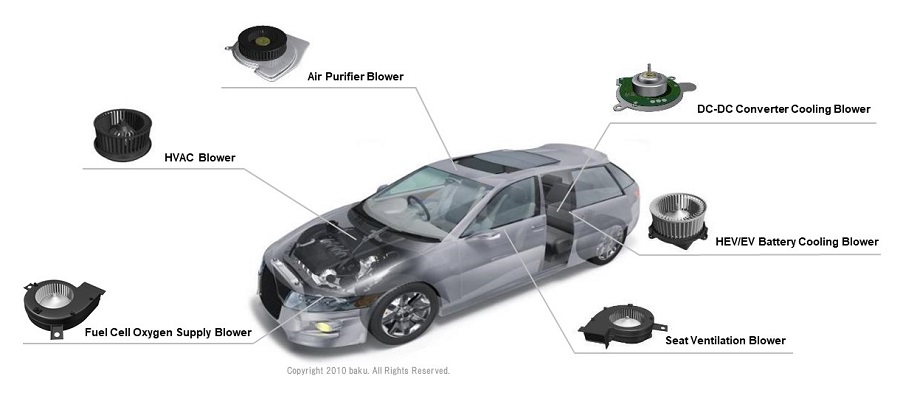

Examples of blower motors in automotive application

- Blower motors for fuel cell oxygen supply

- Blower motors for air purifiers

- Blower motors for DC-DC converter cooling

- Blower motors for HEV/EV battery cooling

Overcome your problems with ASPINA’s HVAC blower motors

The key to blower motor development is to study the electric motor, fan, impeller, circuitry, and other components in detail to build up an accurate understanding of where performance losses occur. ASPINA draws on their expertise built up through many years of development, not only to optimize blowers or their motors to improve their performance, but also to make them smaller, lighter, have longer operating times. The vibration and noise level are reduced to low levels, using our accumulated manufacturing experience and know-how. ASPINA also has extensive scope for customization, so please don't hesitate to contact us.

If you have any questions or would like samples, quotations, consulting on customization etc., please feel free to contact us from our form.

Contact us for more information

- New inquiry

- Prototype

- Upgrade

- Customization

- Your spec

- Literature

- Support

- Others