How to comply with building regulations – ASPINA's solution for decentralised ventilation fans

-

Life environment

-

Home appliance

-

Residential ventilation unit

30 Sep. 2021

ASPINA has years of experience working with the ventilation system industry, and has been developing motors and blowers that meet the latest needs. This time, ASPINA has a proposal for decentralised ventilation fans: to replace the AC motors powering fans to our sinusoidal drive three-phase brushless DC (BLDC) motor. This enables high energy efficiency, high motor speed, and at the same time low motor vibration, which are essential for your products to comply with building regulations.

In this article, we explain factors you need to consider and ASPINA’s solution when developing regulation compliant ventilation fans.

The political and environmental changes surrounding decentralised ventilation fans

Climate change and environmental degradation due to global warming are common issues we face around the world. In response to this continuing threat, humanity needs a new growth strategy to transform itself into a sustainable, competitive economy.

The EU set a goal of net-zero emissions of greenhouse gases by 2050. In the United Kingdom, energy efficiency standards (The Future Homes Standard) are being revised in stages to achieve the government's target of net-zero emissions by 2050 and in January 2021, the "Building Regulations: Approved Documents L, F and Overheating" was announced.

This has an impact on manufacturers in related industries. In building ventilation, performance requirements of ventilation fans rise to higher levels.

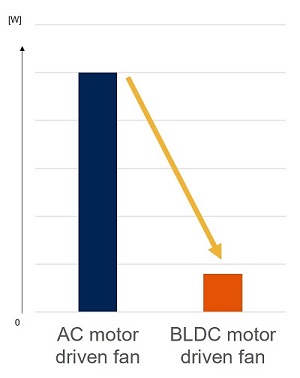

Replacing your AC motor with a BLDC motor can save up to 80% power consumption… but is that enough?

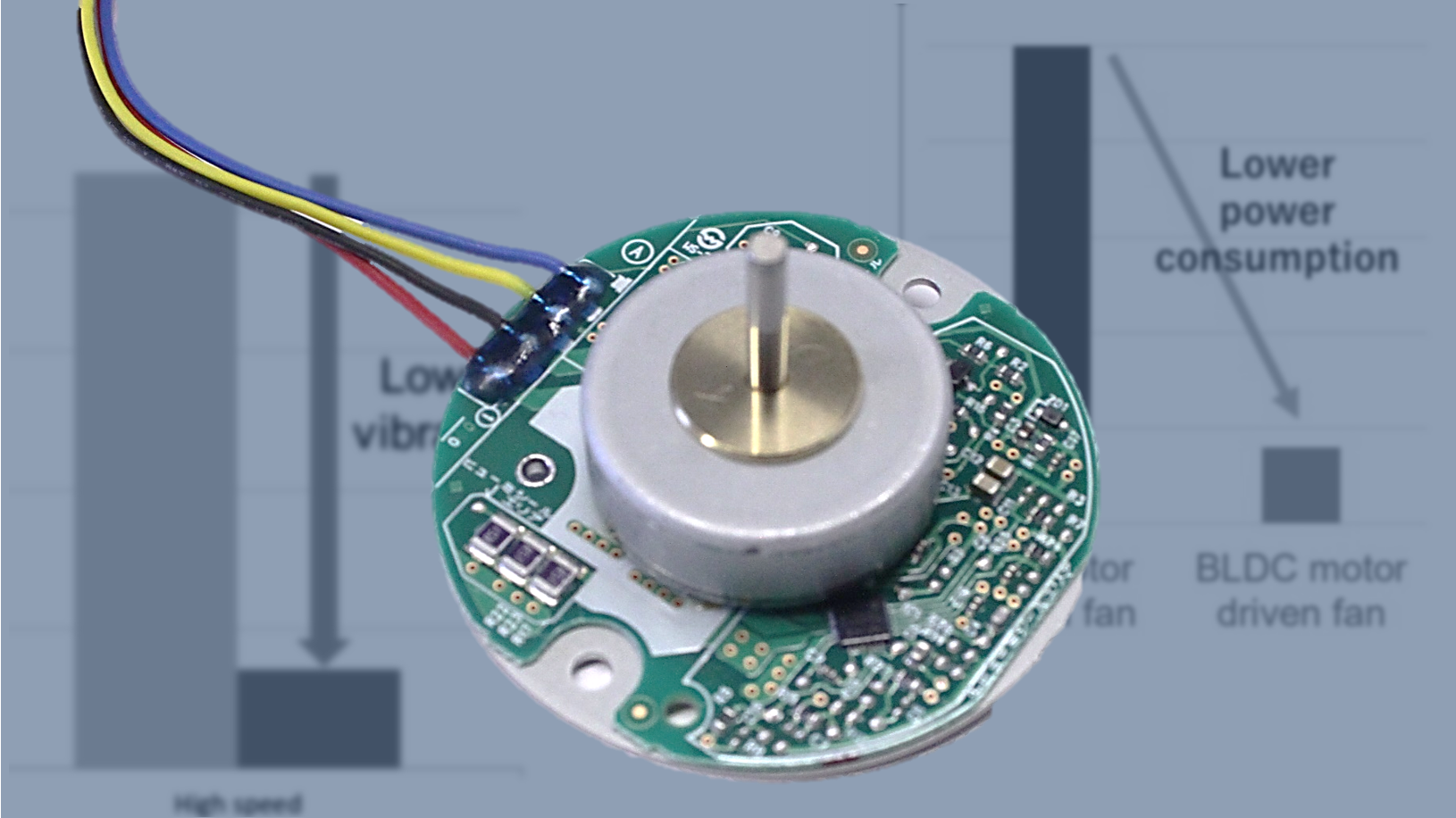

Most decentralised ventilation fans currently in the market are powered by AC motors, which energy efficiency would not meet the new standards. However, by changing the AC motor to a BLDC motor, there will be a significant change in power efficiency. Fans driven by BLDC motors have the potential to save up to 80% of power consumption, compared to fans driven by AC motor.

Power consumption comparison between BLDC motor and AC motor driven fans

Power consumption comparison between BLDC motor and AC motor driven fans

Just change the type of motor for higher efficiency; sounds simple enough. But is motor energy efficiency the only sole issue we need to consider to comply with the latest regulations?

The latest revisions to the U.K. Building Regulations aim to improve the building insulation and airtightness, in order to maintain a healthy living environment. For kitchen and bathroom ventilation the following points must be taken into account:

- The air needs to be exhausted at high pressures from houses that have improved airtightness.

- For more freedom in design of the living spaces in the future, exhaust air ducts are to be adapted more individually to the structure of the building (resulting in ducts that are longer and have more curves).

- The ventilation system needs its power performance to counteract the back pressure of the outside air.

- It is necessary to reduce the power consumption not only by ventilation but also by heating and cooling, humidity control, etc.

In order to meet the new standards and deal with the associated changes, it is necessary to bring motor torque and rotation speed of decentralised ventilation fans to a higher level. Besides that, outstanding energy efficiency has to be achieved at the same time. In the following section, we will explain how this affects motor selection for your regulation compliant decentralised ventilation fan.

Motor vibration – another key point to consider

There are some issues to consider when running motors at high speeds, and motor vibration is one of them. Some types of motors can produce a considerable amount of vibration and also associated noise when running at high speeds, which can be a problem, especially if the motor is going to be used for household products. Therefore, we need to select the right motor that can be used under these circumstances.

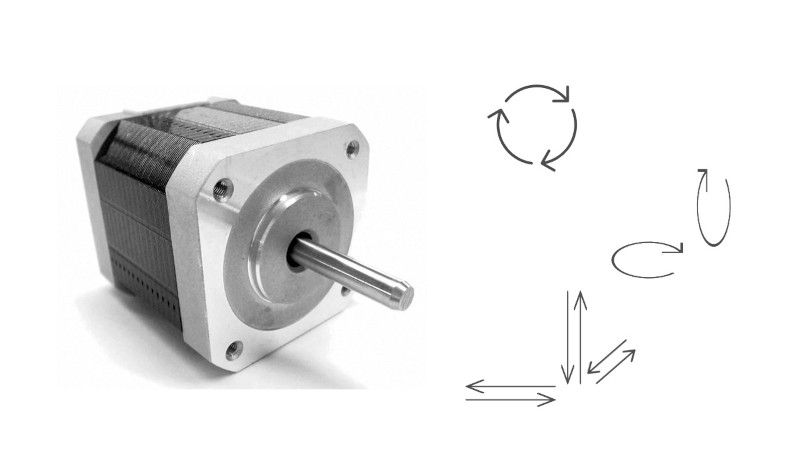

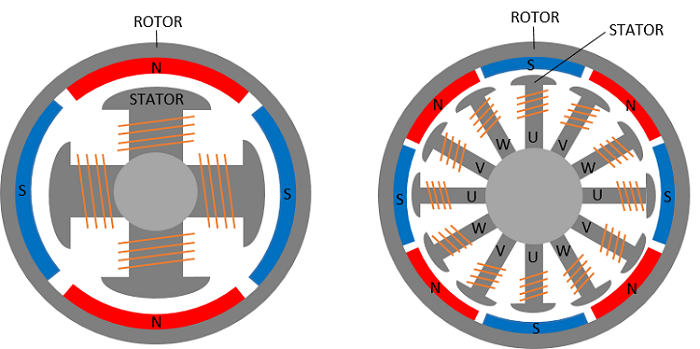

Two typical types of BLDC motors are used in many applications: single-phase BLDC motors and three-phase BLDC motors. Single-phase BLDC motors use two coils, while three-phase BLDC motors use three coils (U, V, W). Single-phase BLDC motors have fewer slots and therefore fewer number of times of switching per rotation than three-phase BLDC motors. This results in more coil oscillations occurring at each switching. Consequently, single-phase BLDC motors are not stable at high rotation speeds and motor vibration (noise) can increase. This is not suitable for “new standard decentralised ventilation fans” that require high motor rotation speed to counteract the high back pressure and longer exhaust ducts. On the other hand, a three-phase BLDC motor has more slots, higher number of switching per rotation, and therefore less motor vibration at high rotation speeds; which is exactly what we need.

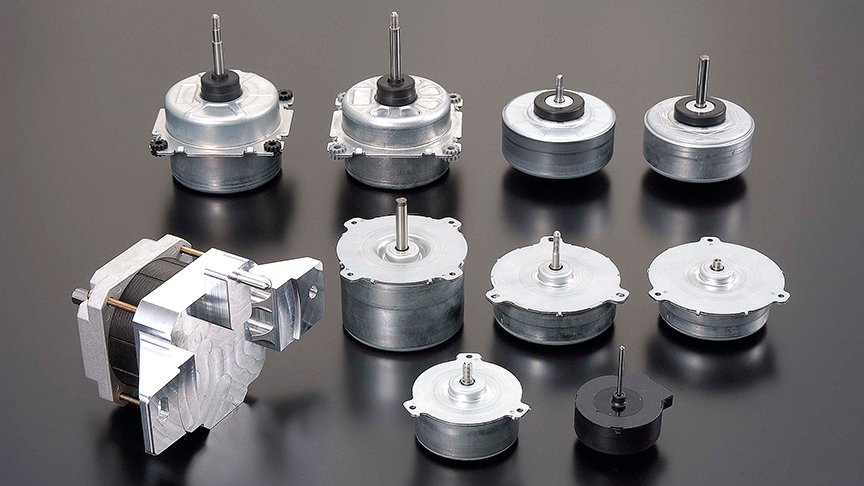

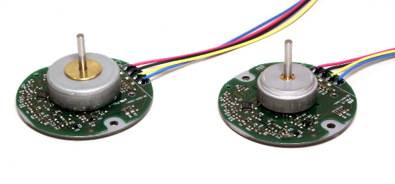

From the left: single-phase 4 pole BLDC motor and three-phase 12 pole BLDC motor

From the left: single-phase 4 pole BLDC motor and three-phase 12 pole BLDC motor

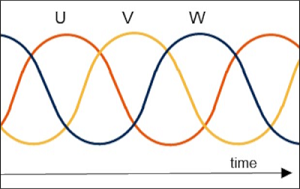

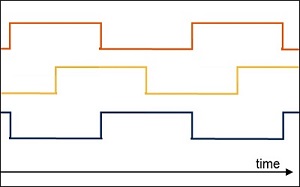

Even lower vibration and power efficiency can be achieved by using sinusoidal drive. Motor drive systems can be divided in to two types: sinusoidal drive and rectangular wave drive. Compared with the rectangular wave drive, which varies the coil voltage in a rectangular wave, the sinusoidal drive, which varies the coil voltage in a sinusoidal wave, allows a smoother rotation. For this reason, motors using sinusoidal drive have a lower motor vibration and noise level than those using the rectangular wave drive, and at the same time have higher energy efficiency.

Waveform at sinusoidal drive

Waveform at sinusoidal drive

Waveform at rectangular wave drive

Waveform at rectangular wave drive

The sinusoidal drive is PWM-controlled and can change the rotation speed linearly. This means that not only can a myriad of rotation speeds be set, but also that the entire fan can be made quieter by avoiding its resonant rotation speed in the program of the fan.

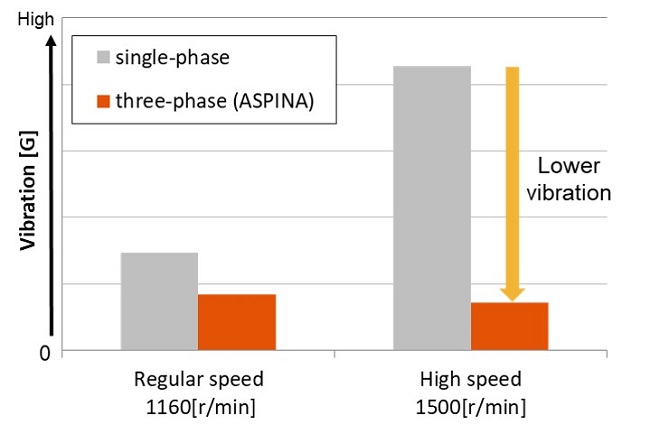

The graph below is the result of a vibration acceleration test. It compares ASPINA’s sinusoidal drive three-phase BLDC motor with a single-phase BLDC motor from an existing ventilation fan in the market. The difference is evident. ASPINA’s sinusoidal drive three-phase BLDC motor has 60% less motor vibration at 1,500 r/min, compared to the single-phase BLDC motor. This is more than enough to comply with the uplifted standards, and meet the needs of decentralised ventilation fan manufactures looking for energy efficient, low vibration motors.

Vibration comparison between single-phase and three-phase BLDC motors

Vibration comparison between single-phase and three-phase BLDC motors

Develop and release your regulation compliant decentralised ventilation fan with speed, using ASPINA’s sinusoidal drive three-phase brushless DC motor

ASPINA’s line-up of sinusoidal drive three-phase brushless DC motor will bring significant improvement in energy efficiency and higher motor rotation speeds to your ventilation fan products, making compliance with the building regulations possible. At the same time, low vibration can be achieved even at the high motor speed range, which is essential for a quiet product.

Another advantage of using our sinusoidal drive three-phase brushless DC motor, is that it will enable a swift release of your product to the market.

With the review of energy efficiency standards continuing to progress, a speedy development and release of your product is crucial. But as all R&D engineers would know, developing a new product, or replacing a part of a current model takes a lot of time and effort. In particular, when using a three-phase BLDC motor in place of an AC motor or single-phase BLDC motor, you would need to design a new drive circuit, which will take a considerate amount of time. However, you can conquer these issues with our product. ASPINA’s line-up of three phase BLDC motors for decentralised ventilation fans have models with built-in drive circuits, eliminating the time to develop a circuit from scratch.

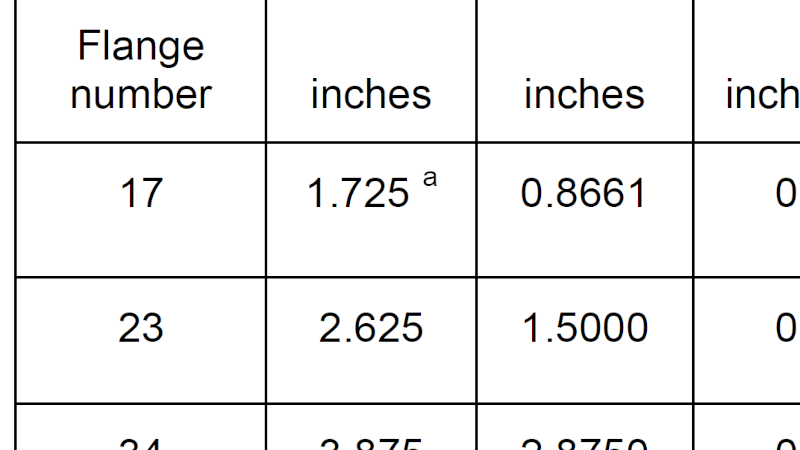

| ASPINA brushless DC motor lineup for ventilation fans | |||||

|---|---|---|---|---|---|

| Drive circuit | Built-in | Not mounted | |||

| Input | 12V | 24V | 12V | 24V | |

| Output | 5W | available | available | available | available |

| 2W | available | available | available | available | |

ASPINA is always of the same mind with our customers. We support your development of regulation compliant products, and will contribute to improve energy efficiency in homes.

Contact us for more information

- New inquiry

- Prototype

- Upgrade

- Customization

- Your spec

- Literature

- Support

- Others